An I-Beam is incredibly strong due to its unique design and the efficient distribution of material.

The I-shaped cross-section, which includes a vertical web and two horizontal flanges, allows the beam to withstand large loads without substantial deformation.

The flanges of the beam bear most of the bending moment created by the load, while the web primarily resists shear forces.

Moreover, the material selection, typically structural steel, contributes to the strength of I-Beams.

Lastly, the way that the I-Beam distributes load throughout its structure reduces bending and deflection, further increasing the beam’s load-bearing capacity.

Introduction

The Introduction section provides an overview of the fundamental concept of an I-Beam and its historical context. It lays the groundwork for the subsequent discussion on the design, material selection, strength, applications, and other aspects of an I-Beam.

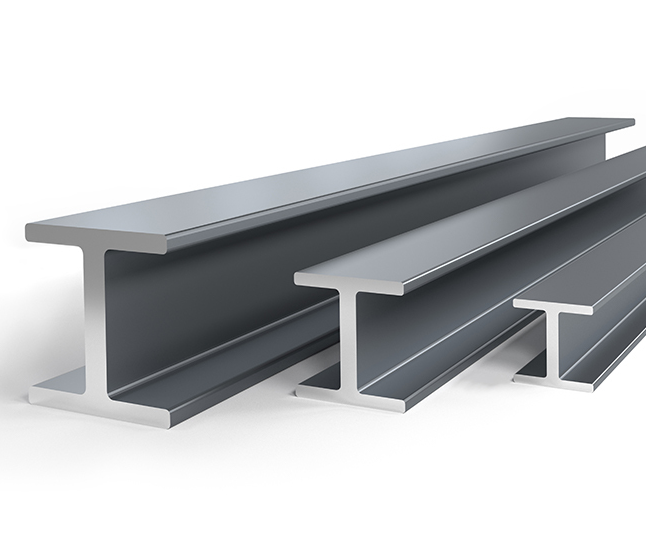

Definition of an I-Beam

An I-Beam, also known as an H-beam, W-beam (for “wide flange”), universal beam (UB), rolled steel joist (RSJ), or double-T (especially in Polish, Bulgarian, Spanish, Italian and German), is a beam with an I or H-shaped cross-section.

Brief History of I-Beam

The I-Beam design has been in use for centuries for the construction of buildings and bridges. However, it was only in the 19th century that the I-Beam took on its current shape.It has since become a cornerstone of modern structural engineering, revolutionizing construction and paving the way for larger, more robust structures.

Design of an I-Beam

The Design of an I-Beam section explores the components that make up an I-Beam, as well as the geometric properties that give it its distinctive shape and remarkable strength.

Components of an I-Beam

An I-Beam consists of three main components: the web, and two flanges. The ‘web’ is the central vertical section, and the ‘flanges’ are the top and bottom parts of the beam, which are typically parallel to each other. The flanges provide resistance to bending movement, while the web provides resistance to shear stress. This combination gives the I-Beam its high load-bearing capacity, allowing it to withstand bending and shear forces better than a simple rectangular bar or other types of beams.

Geometric Properties of an I-Beam

The geometric properties of an I-Beam significantly contribute to its strength and structural performance. The key geometric properties include the height of the web, the width of the flanges, and the thickness of the web and flanges.

- The height of the web contributes to the beam’s ability to withstand bending and deflection. Taller beams generally have greater bending resistance.

- The width of the flanges provides stability and helps to distribute the forces acting on the beam.

- The thickness of the web and flanges impacts the overall strength and weight of the beam. Thicker webs and flanges generally increase the beam’s capacity to carry load, but they also increase the beam’s weight.

Material Selection in I-Beams

The Material Selection in I-Beams section focuses on the types of materials commonly used in I-Beam fabrication and how their properties influence the strength and functionality of the beams.

Commonly Used Materials

I-Beams are typically made from structural steel due to its high strength-to-weight ratio, affordability, and weldability. Structural steel is a category of steel used for making construction materials in a variety of shapes, with I-Beams being one of the most common.

However, I-Beams can also be made from other materials such as aluminum, where a lighter weight is desired, and concrete, which is often reinforced with steel bars or mesh for additional strength. The material choice largely depends on the requirements of the specific application and the balance between cost, weight, strength, and durability.

Material Properties and Their Impact on Strength

The strength of an I-Beam is heavily influenced by the properties of the material from which it is made. For example:

- Stiffness: The stiffness or rigidity of the material, typically measured by the modulus of elasticity, influences the beam’s deflection under load.

- Ductility: The ductility of the material, or its ability to deform under high stress before breaking, can impact the beam’s performance under dynamic or seismic loads.

- Durability: The material’s resistance to environmental conditions, including corrosion, weathering, and decay, can affect the lifespan of the I-Beam and its long-term structural integrity.

By carefully considering the material properties, engineers can design and select I-Beams that provide the necessary strength and performance for their specific application.

Strength of an I-Beam

The Strength of an I-Beam section delves into the crucial role of the I-Beam’s shape in its structural integrity, and how the distribution of load across the beam results in its high strength.

Structural Importance of Shape

The I-Beam’s distinctive I-shaped cross-section, comprising a vertical web and two horizontal flanges, is key to its remarkable strength. The flanges resist bending moments, while the web resists shear forces. This efficient distribution of material means the I-Beam can withstand large loads without substantial deformation.

In essence, by locating most of its material away from the neutral axis (the axis about which the beam bends), the I-Beam makes optimal use of the material’s strength. The neutral axis is the location where the material experiences zero stress during bending. Placing material far from this axis means that it contributes more effectively to the beam’s resistance to bending.

How Load Distribution Increases Strength

The flanges of the beam bear most of the bending moment created by the load, while the web primarily resists shear forces.

This efficient distribution of forces reduces bending and deflection, thereby increasing the beam’s load-bearing capacity.

Furthermore, the moment of inertia, a geometric property related to the distribution of the material about the neutral axis, is considerably larger for an I-Beam than for a solid rectangular beam of equivalent material. A higher moment of inertia implies a higher bending resistance, thus enhancing the overall strength of the I-Beam.

The combined effects of the I-Beam’s shape and the manner in which it distributes load are fundamental to its considerable strength and resilience, making it a favored choice in construction and engineering.

Applications of I-Beams

The Applications of I-Beams section discusses the various areas where I-Beams are commonly used, ranging from building construction and bridges to various other industrial applications.

Use in Building Construction

The primary use of I-Beams is in the construction of buildings. Their high strength-to-weight ratio and efficient load-bearing capacity make them ideal for both residential and commercial construction.I-Beams help to ensure that buildings are strong, durable, and capable of withstanding various environmental factors.

Use in Bridges

Bridge construction is another domain where I-Beams play a crucial role. Bridges require materials that can withstand heavy loads and resist the forces of nature, and I-Beams fit these requirements perfectly.They are particularly common in the construction of simple span bridges, where the I-Beams serve as the main support beams.

Other Industrial Applications

Beyond buildings and bridges, I-Beams have a multitude of other industrial applications.

In sum, I-Beams’ strength, durability, and versatility make them invaluable in a wide array of structural and industrial applications.

Advantages and Limitations of I-Beams

The Advantages and Limitations of I-Beams section explores the numerous benefits that I-Beams offer in construction and engineering, as well as the potential challenges and limitations they present.

Advantages

I-Beams bring a host of advantages to the table. Key among these are:

- Strength: I-Beams are incredibly strong. Their unique design allows them to support high loads with less material than other beam types, leading to a high strength-to-weight ratio.

- Efficiency: The efficient distribution of material in the I-Beam’s shape results in less material waste. This not only saves costs but also aligns with sustainable practices.

- Ease of Use: I-Beams are relatively simple to install and use in construction projects, allowing for efficient building processes.

Limitations and Challenges

Despite their many advantages, I-Beams are not without their limitations:

- Directional Strength: While I-Beams are incredibly strong when subjected to loads in the vertical direction, they are significantly weaker when loads are applied laterally or torsionally. This is due to the asymmetry of their cross-sectional shape.

- Cost: While the use of I-Beams can be more cost-efficient in terms of material usage, the initial cost of high-quality steel or other material I-Beams can be high.

- Corrosion: Unless properly treated or made of corrosion-resistant material, I-Beams can be susceptible to corrosion, especially in environments with high humidity or salt content, such as coastal areas.

Understanding these advantages and limitations allows engineers to make informed decisions about when and where to utilize I-Beams in their designs, leading to more efficient, durable, and effective structures.

Referensi

- I-Beam (Wikipedia)

- Structural Steel (Wikipedia)

- Bridge (Wikipedia)

- Shipbuilding (Wikipedia)

- Rail Tracks (Wikipedia)

- Crane (Machine) (Wikipedia)