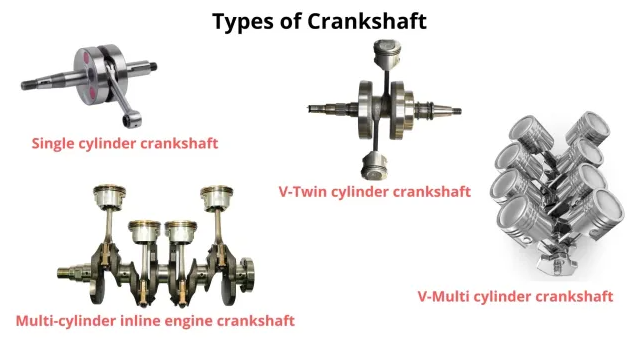

There are several types of crankshafts, each designed for specific applications and engine types.

The most common types include Monolithic Crankshaft, Built-Up (Modular) Crankshaft, Forged Steel Crankshaft, and Cast Iron Crankshaft.

The choice between them depends on factors such as the type and purpose of the engine, material and durability of the crankshaft, cost considerations, and maintenance and service life.

Introduction

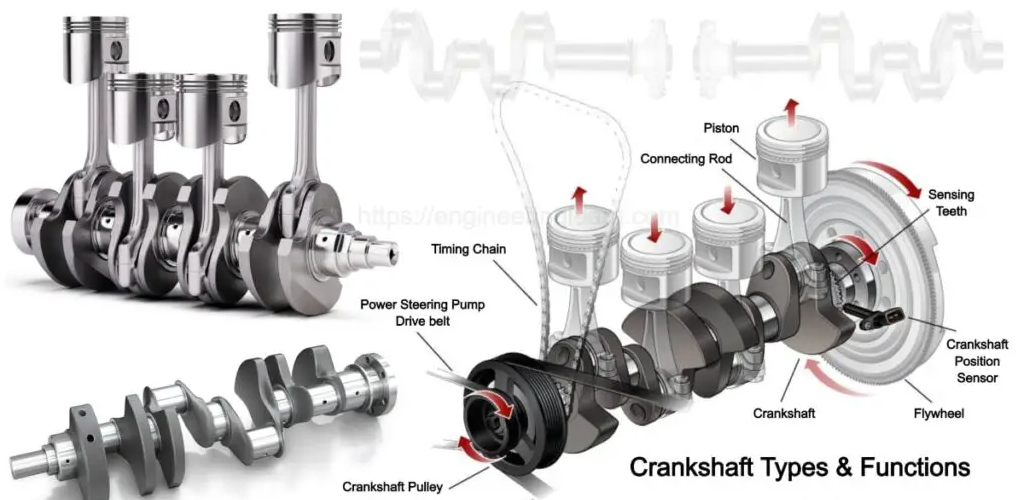

The crankshaft is an integral component of any internal combustion engine. It performs the crucial function of converting the reciprocating linear motion of the pistons into rotational motion.

Definition of a Crankshaft

A crankshaft is a mechanical component that converts reciprocating motion into rotational motion or vice versa.

Importance of Crankshaft in Engines

The crankshaft is a critical part of an engine, serving several vital roles. Not only does it convert the linear, up-and-down motion of the pistons into a rotary motion used to power the vehicle, but it also helps to synchronize the timing of your engine’s valves. Its counterweights help reduce engine vibrations, providing a smoother ride. Without a properly functioning crankshaft, an engine simply cannot operate.

Brief Overview of Different Types of Crankshaft

There are various types of crankshafts, each with its unique set of characteristics, advantages, and disadvantages. These types primarily differ in their construction methods and materials used. The most common types include monolithic crankshafts, built-up (or modular) crankshafts, forged steel crankshafts, and cast iron crankshafts.

Understanding the Components of a Crankshaft

Before delving into the different types of crankshafts, it is important to understand the primary components of a typical crankshaft. These parts include the main journal, crank pin, counterweights, and crank web.

Main Journal

The main journal or simply journal is the portion of the crankshaft that spins within the main bearings, held in the engine block. It forms the axis of rotation for the crankshaft and supports the entire load exerted by the engine’s operation.

Crank Pin

The crank pin, also known as the rod journal, is an eccentrically or off-center located rod that the connecting rods attach to.

Counter Weights

They help reduce engine vibrations and stabilize the crankshaft’s operation. The counterweights also balance the forces exerted on the crank pin, making the engine run smoother.

Crank Web

The crank web, sometimes called the crank cheek, connects the main journal and the crank pin. These webs also house the counterweights and play a crucial role in the crankshaft’s overall balance and strength. The shape and size of the crank webs can significantly impact the crankshaft’s weight and the engine’s overall performance.

Different Types of Crankshaft

Crankshafts come in various types, each designed for specific applications and engine types. Here, we delve into four of the most common types: Monolithic, Built-Up (Modular), Forged Steel, and Cast Iron Crankshafts.

Monolithic Crankshaft

Description and Use

A Monolithic Crankshaft is created from a single piece of material, usually steel or cast iron. The entire crankshaft is then machined from this single piece. It is commonly used in small to medium-sized engines due to its compact nature and relative simplicity in manufacturing.

Advantages and Disadvantages

However, they can be challenging and expensive to manufacture, especially for large, complex engines.

Built-Up (or Modular) Crankshaft

Description and Use

A Built-Up or Modular Crankshaft is assembled from several pieces. The main journals and crankpins are usually bolted together. This type of crankshaft is mainly used in large engines, like marine diesel engines, where the crankshaft size would make a monolithic design unfeasible.

Advantages and Disadvantages

The primary advantage of a Built-Up Crankshaft is its ease of construction and repair.However, it can be less strong and durable compared to monolithic designs due to potential weaknesses at the joints.

Forged Steel Crankshaft

Description and Use

A Forged Steel Crankshaft is created from a single billet of steel that has been heated and then hammered into shape. This process results in a crankshaft with superior strength and toughness, making it ideal for high-performance and heavy-duty applications.

Advantages and Disadvantages

The key advantage of Forged Steel Crankshafts is their exceptional strength and durability, allowing them to withstand high stress and prolonged use. However, the forging process makes them more expensive to produce than other types of crankshafts.

Cast Iron Crankshaft

Description and Use

A Cast Iron Crankshaft is created by pouring molten iron into a mold that has been shaped like the desired crankshaft. This type of crankshaft is commonly found in smaller engines where the demands on the crankshaft are less.

Advantages and Disadvantages

Cast Iron Crankshafts are relatively inexpensive to produce and have good wear resistance, making them a good choice for small to medium-sized engines. However, they lack the strength of forged steel crankshafts and may not be suitable for high-performance or heavy-duty applications.

Factors to Consider When Choosing a Crankshaft

When choosing a crankshaft for an engine, several factors need to be taken into account. These factors include the type and purpose of the engine, material and durability of the crankshaft, cost considerations, and maintenance and service life.

Engine Type and Purpose

The type and purpose of the engine are critical factors when choosing a crankshaft. A high-performance engine, such as those used in race cars, may require a forged steel crankshaft due to its superior strength and ability to withstand high stresses. On the other hand, a smaller, general-purpose engine may only require a cast iron crankshaft.

Material and Durability

The material of the crankshaft affects its durability and longevity.On the other hand, cast iron crankshafts may be more affordable but are less durable under high-stress conditions. Therefore, the choice of material should align with the intended use of the engine.

Cost Considerations

The cost of the crankshaft can be a determining factor in choosing one. Forged steel crankshafts, while durable and high-performing, are also more expensive than cast iron or monolithic crankshafts.

Maintenance and Service Life

Consider the maintenance needs and expected service life of the crankshaft.he service life is also related to the type of material: forged steel typically lasts longer than cast iron.

When choosing a crankshaft, one should consider not only the initial purchase and installation costs but also the ongoing maintenance costs and the potential need for replacement parts over the life of the engine.

How the Crankshaft Affects Engine Performance

The crankshaft plays a crucial role in engine performance, impacting engine speed, power output, and fuel efficiency. Understanding how it influences these areas can help you make informed decisions when choosing a crankshaft.

Impact on Engine Speed

The crankshaft plays a significant role in determining the engine’s speed. The balance and weight of the crankshaft can affect the engine’s rev limit. A well-balanced and lighter crankshaft can reduce rotational inertia, allowing the engine to spin up faster, thus potentially increasing the engine’s speed.

Impact on Power Output

The power output of an engine is also directly related to the crankshaft design. The strength and durability of the crankshaft material can allow the engine to handle higher compression ratios, which can result in increased power output. Furthermore, a well-balanced crankshaft can minimize power loss due to vibration, thereby maximizing power output.

Impact on Fuel Efficiency

Crankshaft design can also impact an engine’s fuel efficiency. A lighter crankshaft requires less energy to rotate, potentially improving the engine’s fuel efficiency. Additionally, a well-balanced crankshaft reduces vibration and wear, leading to more efficient operation over time.

Future Trends in Crankshaft Design

As technology advances, so does the design and manufacturing of crankshafts.

Developments in Material Science

Future developments in material science will likely bring about new materials for crankshaft design. These new materials may offer increased strength, reduced weight, or improved durability. The use of composites or exotic alloys might offer these advantages and potentially revolutionize the crankshaft industry.

Technological Advancements

Technological advancements are likely to continue influencing crankshaft design. Improved manufacturing techniques, such as more precise machining or advanced forging methods, can lead to more efficient and durable crankshafts. Additionally, advancements in computational modeling can lead to improved crankshaft designs that optimize weight distribution and reduce vibrations.

Environmental Considerations

As the world becomes more conscious of environmental impacts, environmental considerations will also play a part in the future of crankshaft design. This may result in the development of crankshafts designed for use in more fuel-efficient engines or engines that operate on alternative fuels. The drive for sustainability might also influence the materials used in crankshaft production, with a greater emphasis on recyclable or environmentally friendly materials.

In conclusion, while the basic principles of crankshaft design and function remain constant, the materials, technologies, and considerations used in their creation are continually evolving.

Referensi

- Crankshaft – Wikipedia

- Forging – Wikipedia

- Cast Iron – Wikipedia

- Engine Power – Wikipedia

- Fuel Efficiency – Wikipedia

- Materials Science – Wikipedia

- Environmental Technology – Wikipedia