The essence of the mechanical world lies in understanding the significance and nuances of its parts, and the world of automobiles is no exception. A piece of machinery vital to the engine’s functioning, the crankshaft, has long been a subject of debate and engineering insights. An underlying question in this realm is, is a heavier crankshaft better?

We’ll dive into this query, shedding light on the complexities of the crankshaft’s weight and how it affects overall engine performance. We’ll avoid cliched transitional phrases, opting for a more conversational, story-driven approach.

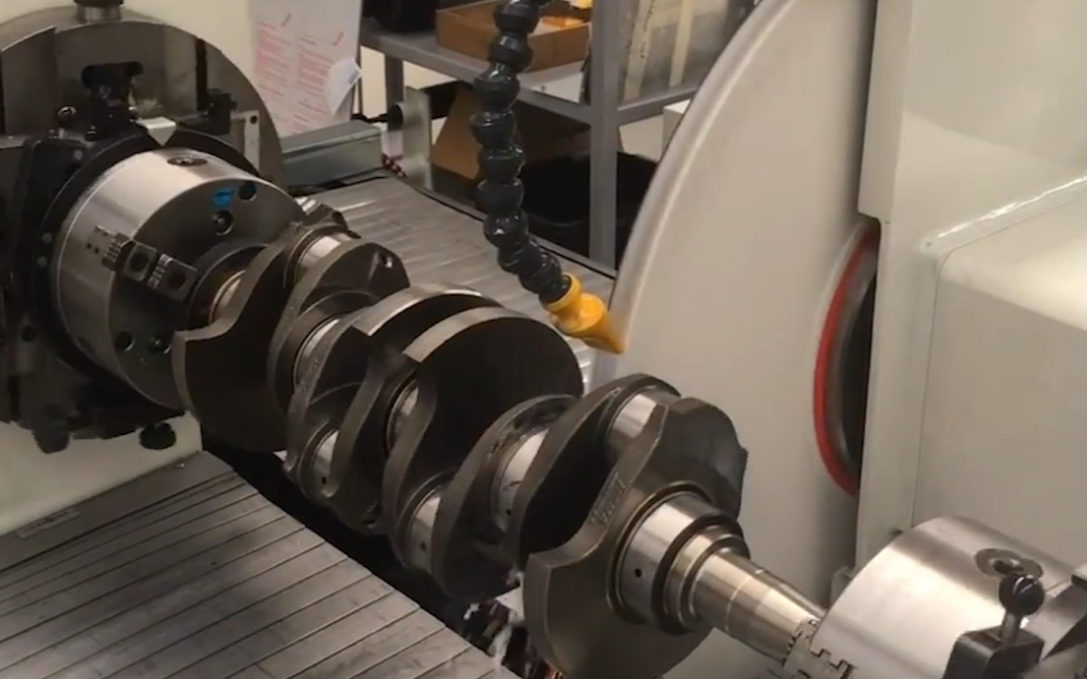

To appreciate the question at hand, it’s vital to understand the crankshaft’s role. Located within the engine block, the crankshaft plays a key role in converting the linear motion of pistons into rotational motion, essentially the driving force behind any automobile. The effectiveness of this transformation is influenced by the weight of the crankshaft; a critical factor that engineers across the globe contemplate.

The argument in favor of a heavier crankshaft centers around one crucial benefit – smoother engine operation. An increased weight allows for a larger inertia mass, ensuring that the engine runs more steadily, providing a smoother ride overall. Heavier crankshafts are seen to reduce the harshness and vibration during operation, resulting in less wear and tear of engine components over time.

However, is it fair to conclude that a heavier crankshaft is definitively better? As with many aspects of automotive engineering, the answer is not black and white. While a heavier crankshaft does offer some advantages, it brings along a share of potential drawbacks.

One of the most significant considerations against a heavier crankshaft is its impact on engine responsiveness. The increased inertia of a weightier crankshaft means that the engine might take longer to accelerate or decelerate. In the realm of sports cars and performance-oriented vehicles, this can be a crucial disadvantage, compromising the quick throttle response desired by drivers.

Another issue surfaces with respect to fuel efficiency. A heavier crankshaft means more energy is required to initiate movement, resulting in more fuel consumption. As environmental concerns become ever more significant, fuel efficiency is a paramount consideration for engineers and consumers alike.

Moreover, the added weight of the crankshaft can lead to greater stress on engine bearings, potentially leading to premature failure or more frequent maintenance requirements. These disadvantages of a heavier crankshaft might offset the advantages, making it less than the perfect solution it initially appears to be.

In conclusion, a heavier crankshaft is not universally better. Its suitability largely depends on the vehicle’s intended use. For luxury vehicles, where the smoothness of the ride is more important, a heavier crankshaft might indeed be beneficial. Conversely, in performance-oriented vehicles where quick response and fuel efficiency are prioritized, a lighter crankshaft might be the superior choice.

Understanding the role and impact of the crankshaft’s weight in the engine and its overall functioning is a fascinating exploration into the world of automotive mechanics. Whether a heavier crankshaft is better is not a one-size-fits-all question but a subject of context, preference, and design priorities.

Understanding the Role of the Crankshaft

The crankshaft plays a crucial role in any engine block. This integral component is responsible for converting the linear motion of pistons into rotational motion – the essential driving force behind any vehicle. The effectiveness of this conversion is significantly influenced by the weight of the crankshaft, thus introducing the question at hand – is a heavier crankshaft better?

Benefits of a Heavier Crankshaft

A more substantial crankshaft offers certain advantages, chief among them being smoother engine operation. This is because the larger the crankshaft’s mass, the greater its inertia, allowing the engine to run more steadily and the ride to be smoother. Heavier crankshafts can mitigate harsh vibrations during operation, reducing wear and tear on engine components over time.

Drawbacks of a Heavier Crankshaft

Despite the advantages, a heavier crankshaft also comes with several potential drawbacks. The increased inertia might reduce engine responsiveness, meaning it could take longer for the engine to accelerate or decelerate. This could be a significant disadvantage in performance-oriented vehicles where quick throttle response is vital. Furthermore, a heavier crankshaft requires more energy to initiate movement, which may lead to increased fuel consumption – a concerning factor in the context of fuel efficiency and environmental impact.

Impact on Engine Bearings and Maintenance

An additional consideration is that a heavier crankshaft can induce greater stress on engine bearings, potentially leading to premature failure or necessitating more frequent maintenance. This could offset the advantages of smoother operation and reduced vibrations, posing significant challenges in the long run.

The Dependence on Vehicle’s Intended Use

The question of whether a heavier crankshaft is universally better does not have a clear-cut answer. It largely depends on the vehicle’s intended use. For luxury vehicles, where the smoothness of the ride is prioritized, a heavier crankshaft may be beneficial. However, in performance-oriented vehicles, where quick response and fuel efficiency are of greater concern, a lighter crankshaft could be the superior choice.

Conclusion: A Subject of Context, Preference, and Design Priorities

Understanding the role and impact of the crankshaft’s weight in the engine and its overall functioning is a fascinating exploration into the world of automotive mechanics. Whether a heavier crankshaft is better is not a one-size-fits-all question but a subject of context, preference, and design priorities. Thus, it’s crucial to consider various factors, such as engine design and vehicle purpose, when evaluating the optimal crankshaft weight.