To maintain the peak performance of an engine, it is crucial to ensure the straightness of the connecting rods. This article will outline the importance and methods of how to check connecting rods for straightness, promoting efficient engine function and longevity.

The Vital Role of Connecting Rod Straightness

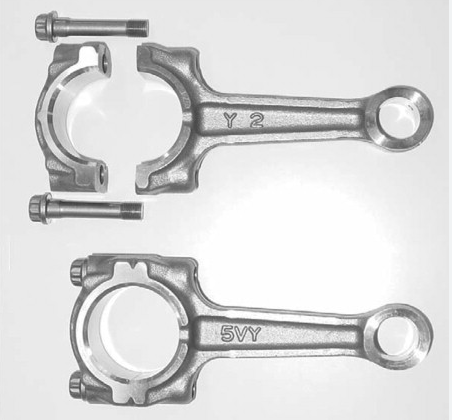

Connecting rods are pivotal components in an engine’s operation, transferring motion from the piston to the crankshaft. If these rods are not straight, the engine’s balance and timing can be disrupted, leading to diminished performance and, in severe cases, catastrophic engine failure. Hence, it is paramount to check their straightness, particularly during engine assembly or overhaul.

Tools Required for Checking Connecting Rod Straightness

The primary tools needed to check the straightness of connecting rods are a surface plate and a dial indicator. The surface plate provides a level reference point, while the dial indicator measures the rod’s straightness to a high degree of accuracy.

Procedure to Check Connecting Rod Straightness

- Prepare the Connecting Rod: Clean the connecting rod thoroughly to ensure there are no contaminants that can affect the measurements.

- Set up the Dial Indicator: Position the connecting rod on the surface plate and set up the dial indicator so its plunger rests against the side of the rod.

- Measure the Rod: Slowly roll the connecting rod while watching the dial indicator’s needle. Any significant needle movement signifies a bend in the rod.

- Interpret the Results: Compare the measurements with the manufacturer’s specifications for acceptable tolerance levels.

Steps to Take After Measurements

If the connecting rod is found to be bent, it is essential to replace it or have it professionally straightened to prevent engine damage. It is not recommended to try straightening the rod at home, as improper handling can weaken the rod’s structure and lead to failure under the engine’s high-pressure operation.

By understanding how to check connecting rods for straightness, you can play a crucial role in maintaining your engine’s integrity and performance. This simple yet effective check can prevent potential engine damage, save on costly repairs, and extend your engine’s lifespan.