The production of connecting rods, a vital component in internal combustion engines, involves an intricate process. The manufacturing of these rods must be precise to ensure their functionality and durability. The process typically involves casting or forging, followed by a series of machining and finishing operations.

The Raw Materials and Initial Process

Connecting rods are typically made from steel or aluminum alloys. Steel is often used for high-performance applications due to its superior strength and durability, while aluminum alloys, being lighter, are used in engines where weight reduction is a priority.

Casting or forging forms the initial shape of the connecting rod. In casting, molten metal is poured into a mold that has the shape of the rod. Once the metal has cooled and solidified, the mold is removed. Forging, on the other hand, involves heating a piece of metal until it’s malleable, and then using a die to shape it into the form of the rod. Forged rods are generally stronger than cast rods due to the aligned grain structure created during the forging process.

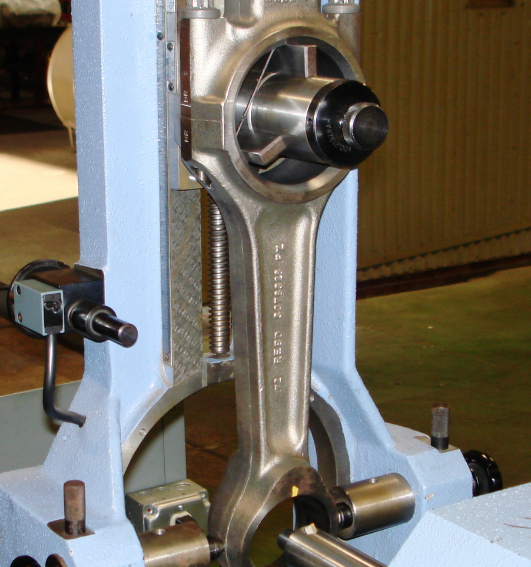

Machining the Connecting Rod

After casting or forging, the rods undergo a series of machining processes to achieve the final shape and to ensure precision. This typically includes milling to remove excess material and to form the big and small ends of the rod, drilling to create the oil passage, and broaching to form the keyways in the big end of the rod.

Heat Treatment and Surface Finishing

Heat treatment is a crucial step in the production of connecting rods. It involves heating and cooling the rods under controlled conditions to improve their mechanical properties, such as hardness and toughness. This makes the rods more durable and resistant to the extreme pressures and temperatures they will encounter in the engine.

Surface finishing processes, such as shot peening and polishing, are also carried out. Shot peening involves bombarding the surface of the rod with small spherical shot to induce compressive stresses, which helps to increase fatigue resistance. Polishing helps to remove any surface imperfections and improve the rod’s aesthetic appearance.

Quality Control and Testing

Quality control is a critical part of the connecting rod production process. Each rod is inspected and measured to ensure it meets the required specifications. Non-destructive testing methods, such as magnetic particle inspection, may also be used to check for any internal or surface defects that could affect the rod’s performance or longevity.

In conclusion, the production of connecting rods involves a complex series of processes, each of which must be carried out with precision and care. From the selection of the raw material to the final quality control checks, every step plays a crucial role in producing a connecting rod that can withstand the extreme conditions within an engine and deliver reliable performance.