Conrod construction is an essential aspect of internal combustion engines, responsible for translating the linear motion of the piston into the rotational motion of the crankshaft. Connecting rods, or conrods, are critical components in the operation of an engine, as they directly influence its performance, efficiency, and reliability.

Connecting rods have a complex design that must withstand high loads and stresses. They are typically made from steel, aluminum, or titanium, each offering specific advantages depending on the application. Steel conrods are known for their strength and durability, making them ideal for high-performance and heavy-duty engines. On the other hand, aluminum conrods are lightweight, reducing the overall mass of the engine and allowing for higher RPMs. Titanium conrods provide a balance between strength and weight, often used in high-performance racing engines.

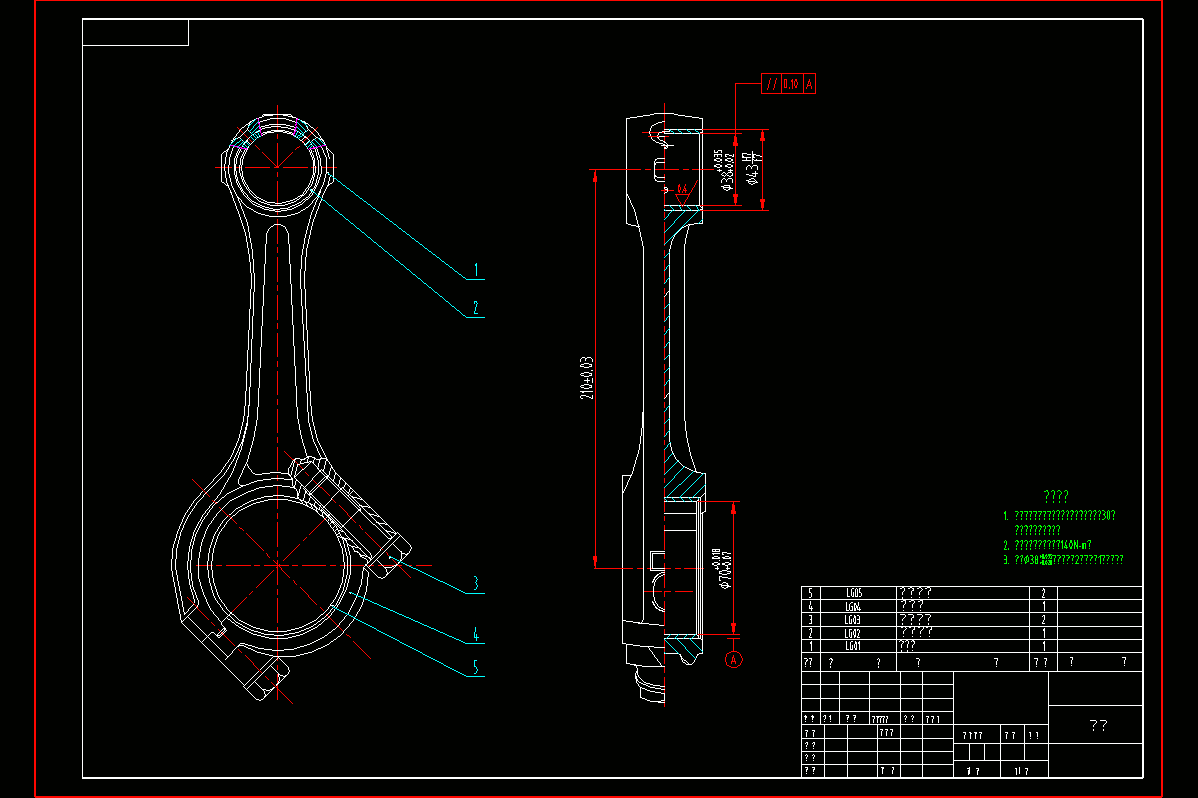

The geometry and design of conrods directly impact engine performance. The length of a connecting rod, known as the center-to-center distance, affects the engine’s stroke and displacement. A longer conrod can lead to a smoother operation, while a shorter one may result in higher torque output. Balancing the weight of connecting rods is crucial to minimize vibrations and ensure consistent engine performance.

Various manufacturing techniques are employed to produce high-quality conrods. Forged conrods offer increased strength and durability, as they are formed under high pressure and temperature. This process aligns the metal grains, providing an improved grain structure and better resistance to fatigue. Powder metallurgy is another method used to manufacture connecting rods, where metal powders are pressed into shape and then sintered at high temperatures. This technique allows for complex shapes and precise tolerances, making it suitable for high-performance applications.

To maintain optimal engine performance, regular inspection and maintenance of connecting rods are necessary. Signs of wear or damage, such as cracks, scoring, or excessive play in the bearing, should be addressed immediately. Replacing worn conrods with new, high-quality components can significantly improve engine performance and longevity.

In conclusion, conrod construction plays a vital role in the overall performance and efficiency of internal combustion engines. The choice of materials, design, and manufacturing techniques directly impacts the engine’s output, while proper maintenance ensures reliable operation. By understanding the intricacies of conrod construction, engineers can optimize engine designs to meet the ever-evolving demands of modern automotive and industrial applications.

Introduction to Conrod Construction

Conrod construction involves the design, material selection, and manufacturing of connecting rods, which are essential components in internal combustion engines. Their primary function is to convert the reciprocating motion of the piston into the rotational motion of the crankshaft. This introduction provides an overview of the various aspects involved in conrod construction and its significance in engine performance.

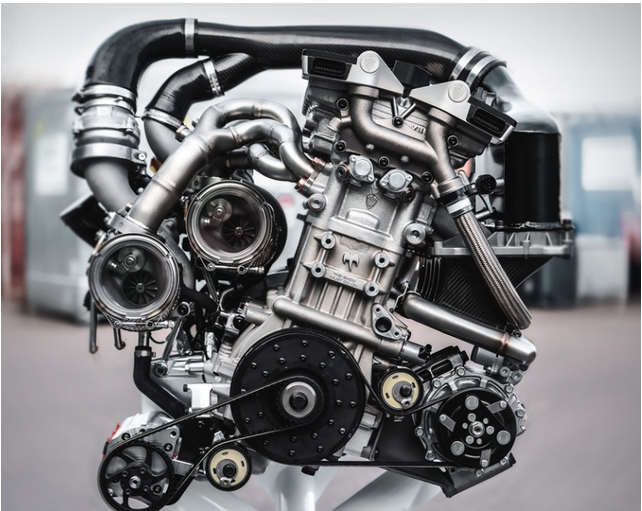

Basics of Internal Combustion Engines

Internal combustion engines generate power through a series of controlled explosions within cylinders, resulting in the motion of pistons. These engines are widely used in automotive, industrial, and power generation applications. Understanding the basics of internal combustion engines is crucial to appreciating the role of connecting rods and the importance of their construction.

Function of Connecting Rods in Engines

Connecting rods play a critical role in transferring the linear motion of the pistons to the rotational motion of the crankshaft. This process is essential for transforming the engine’s power into a usable form to drive the vehicle or machinery. Connecting rods must be strong, lightweight, and durable to maintain optimal engine performance and efficiency.

Common Materials Used in Conrod Construction

4.1 Steel Conrods

Steel is a widely used material for conrod construction due to its strength and durability. Steel conrods are suitable for high-performance and heavy-duty engines, where reliability and longevity are crucial. The strength of steel allows it to withstand high loads and stresses, contributing to a longer service life.

4.2 Aluminum Conrods

Aluminum conrods are lightweight and capable of achieving higher RPMs, which can improve engine performance. The reduced mass of aluminum conrods contributes to decreased inertia, allowing the engine to respond more quickly to changes in load. However, aluminum conrods may not be as durable as steel or titanium options, especially under extreme conditions.

4.3 Titanium Conrods

Titanium conrods offer a balance between strength and weight, making them ideal for high-performance racing engines. Although more expensive than steel or aluminum, titanium provides excellent durability and fatigue resistance, which are essential for demanding applications.

Geometry and Design Considerations

5.1 Center-to-Center Distance

The center-to-center distance is the length of the connecting rod between the centers of the two bearing surfaces. This measurement influences engine stroke and displacement, which in turn affect torque output and overall engine performance.

5.2 Effects on Engine Stroke and Displacement

The length of the connecting rod directly impacts engine stroke, the distance a piston travels within the cylinder. A longer stroke can lead to increased torque output, while a shorter stroke can provide higher RPM capabilities. Adjusting conrod length is one way to modify engine performance characteristics.

5.3 Balancing Conrod Weight

Balancing the weight of connecting rods is essential for minimizing engine vibrations and maintaining consistent performance. An imbalance in conrod weight can lead to uneven forces on the crankshaft, causing vibration and potential damage to engine components.

Manufacturing Techniques for Conrods

6.1 Forging Process

Forging is a common manufacturing technique for conrods that involves forming the connecting rod under high pressure and temperature. This process results in improved grain structure and better resistance to fatigue, contributing to the overall strength and durability of the conrod.

6.2 Powder Metallurgy

Powder metallurgy is another method used to produce connecting rods, where metal powders are pressed into shape and sintered at high temperatures. This technique allows for complex shapes and precise tolerances, making it suitable for high-performance applications.

Importance of Conrod Inspection and Maintenance

7.1 Identifying Signs of Wear or Damage

Regular inspection of connecting rods is crucial to maintaining engine performance and preventing damage.

Signs of wear or damage include cracks, scoring, or excessive play in the bearing. Identifying these issues early can help prevent more severe problems and potential engine failure.

7.2 Replacement of Worn Conrods

Replacing worn or damaged connecting rods with new, high-quality components can significantly improve engine performance and longevity. Regular maintenance and timely replacement of conrods are essential for maintaining optimal engine operation.

Impact of Conrod Construction on Engine Performance

The construction of connecting rods plays a vital role in engine performance, as their design, material, and manufacturing techniques directly affect power output, efficiency, and reliability. Optimizing conrod construction can lead to improved engine characteristics, such as increased torque or higher RPM capabilities.

Achieving Optimal Efficiency and Reliability

Optimizing conrod construction involves selecting the right materials, designs, and manufacturing techniques to balance performance, efficiency, and reliability. By understanding the intricacies of conrod construction, engineers can create tailored solutions to meet the specific requirements of various engine applications.

High-Performance Applications and Racing Engines

In high-performance and racing engines, the demands on connecting rods are much higher, requiring advanced materials, precise manufacturing, and specialized designs. Conrods for these applications must provide exceptional strength, durability, and fatigue resistance while minimizing weight and inertia.

Custom Conrod Design for Unique Engine Requirements

Custom conrod designs can be developed to meet the unique requirements of specific engine applications. These designs may involve variations in length, weight, or geometry, as well as the use of advanced materials or manufacturing techniques. Custom conrods can help optimize engine performance, efficiency, and reliability in specialized applications.

Innovations in Conrod Materials and Manufacturing

Advancements in materials science and manufacturing technologies have led to innovations in conrod construction. New materials, such as carbon fiber composites or metal matrix composites, offer unique properties that can further improve conrod performance. Additionally, advanced manufacturing techniques, such as 3D printing or additive manufacturing, can create complex shapes and structures that were previously impossible.

Challenges in Conrod Production

Producing high-quality connecting rods comes with various challenges, including maintaining precise tolerances, controlling material properties, and ensuring consistent quality. Manufacturers must address these challenges to create conrods that meet the demands of modern engines.

The Role of Quality Control in Conrod Manufacturing

Quality control is essential in conrod manufacturing to ensure consistent performance, durability, and reliability. Rigorous testing and inspection procedures are used to verify that conrods meet design specifications and performance requirements. This process helps to minimize potential issues and maintain high standards throughout the manufacturing process.

Advances in Conrod Design Software

Modern conrod design software enables engineers to create, analyze, and optimize connecting rod designs using advanced computer simulations. This technology allows for rapid prototyping, iteration, and optimization of conrod designs, resulting in improved performance and efficiency.

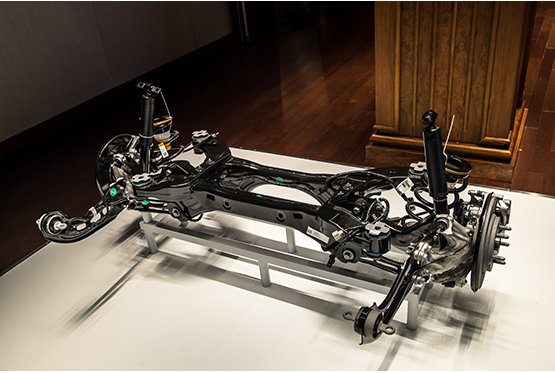

Understanding Engine Vibration and Balancing

Engine vibration is an important consideration in conrod construction, as it can affect overall performance, comfort, and component longevity. Balancing the weight of connecting rods is essential for minimizing vibrations and ensuring consistent engine operation.

The Future of Conrod Construction

As engine technology continues to evolve, so too will conrod construction. Advanced materials, manufacturing techniques, and design software will enable the development of more efficient, reliable, and high-performing connecting rods. These innovations will help to meet the ever-growing demands of modern automotive, industrial, and power generation applications.

Engine Optimization and Modern Automotive Applications

Engine optimization involves refining various components, including conrods, to improve performance, efficiency, and emissions. Modern automotive applications demand engines that are powerful, fuel-efficient, and environmentally friendly. Conrod construction plays a crucial role in meeting these requirements.

Environmental Considerations in Conrod Design

Environmental considerations are increasingly important in conrod design, as the automotive industry shifts towards more sustainable solutions. Lightweight materials, reduced friction, and optimized designs can help minimize emissions and improve fuel efficiency. These efforts contribute to a reduced environmental impact and support the transition to greener transportation.

Conrod Construction in Alternative Engine Types

Alternative engine types, such as rotary or opposed-piston engines, also rely on connecting rods to transfer motion and generate power. While the design and function of conrods in these engines may differ from those in traditional internal combustion engines, the principles of conrod construction remain crucial to their performance and efficiency.

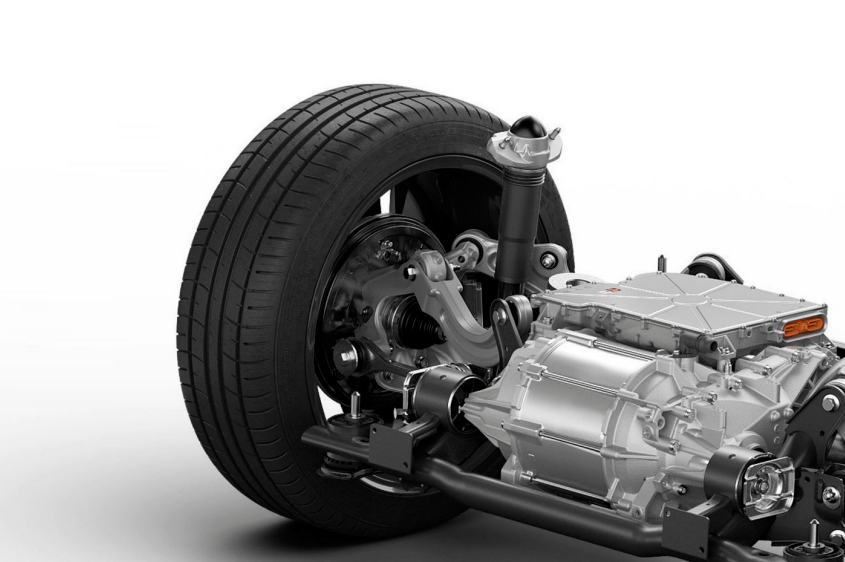

The Role of Conrods in Hybrid Engines

In hybrid engines, which combine internal combustion engines with electric motors, connecting rods still play a critical role in transferring power from the combustion process. Optimizing conrod construction in hybrid engines can help improve overall efficiency and performance, supporting the shift towards more sustainable transportation solutions.

Conrod Construction in Electric Vehicle Applications

Although electric vehicles primarily rely on electric motors for propulsion, some designs incorporate internal combustion engines as range extenders or generators. In these applications, conrod construction remains essential for ensuring efficient power generation and transfer from the combustion process.

Conrods in Aerospace and Aviation

Connecting rods are also critical components in aircraft engines, where they must withstand extreme loads and operating conditions. In these applications, conrod construction focuses on strength, durability, and lightweight materials to minimize weight and maximize performance.

Conrod Construction in Marine Engines

Marine engines, used in boats and ships, also rely on connecting rods to transfer power from the combustion process. Conrod construction in marine engines must account for the unique operating environment, which may involve exposure to corrosive elements, fluctuating loads, and high levels of vibration.

Concluding Thoughts on Conrod Construction

Conrod construction plays a vital role in the performance, efficiency, and reliability of internal combustion engines across various applications. By understanding the intricacies of conrod design, materials, and manufacturing, engineers can optimize engines to meet the ever-evolving demands of the automotive, industrial, aerospace, and marine industries. As technology continues to advance, conrod construction will adapt to support the development of more efficient, high-performing, and environmentally friendly engines.