In an internal combustion engine, a connecting rod serves as a crucial component that transmits power from the piston to the crankshaft.

It translates the linear, reciprocating motion of the piston into the rotational motion required for the engine’s operation.

Introduction

The piston-connecting rod mechanism is an essential part of almost every internal combustion engine, serving as the heart of the engine’s functionality. The role of the connecting rod is especially crucial in translating the energy created in the combustion chamber into a force that moves the vehicle. Understanding the detailed mechanics of this piston-connecting rod mechanism not only provides insights into the engine’s operation but also helps in diagnosing potential engine problems and maintaining vehicle performance.

The Importance of the Piston-Connecting Rod Mechanism in Engines

The piston-connecting rod mechanism is of utmost importance in the operation of engines. The connecting rod connects the piston to the engine’s crankshaft, converting the linear motion of the piston into rotational motion that powers the wheels.The performance, efficiency, and reliability of an engine significantly depend on this mechanism’s function.

Brief Overview of the Article’s Content

This article will delve into the vital role that the connecting rod plays in an engine’s operation. We will explore the basic function of a piston and a connecting rod, the design and construction of connecting rods, and the process of assembling them with the piston. The article also touches on maintenance tips and troubleshooting methods for piston-connecting rod mechanisms. Whether you’re an automotive enthusiast, an engineering student, or a curious individual, this in-depth look into the role of the connecting rod in a piston’s operation will surely enlighten you.

Understanding the Basics

To comprehend how a piston and a connecting rod work together in an engine, we first need to understand their basic definitions and roles individually.

Definition and Role of a Piston

A piston is a cylindrical component that moves up and down (reciprocates) inside the cylinder of an internal combustion engine. It is a fundamental component of the engine as it forms one wall of the combustion chamber where fuel and air mix, combust, and produce energy. The piston, subjected to the explosive force of this combustion, moves downward, transmitting this force to the connecting rod.

The piston’s design, including its size, weight, and material, can significantly impact an engine’s performance, fuel efficiency, and durability.

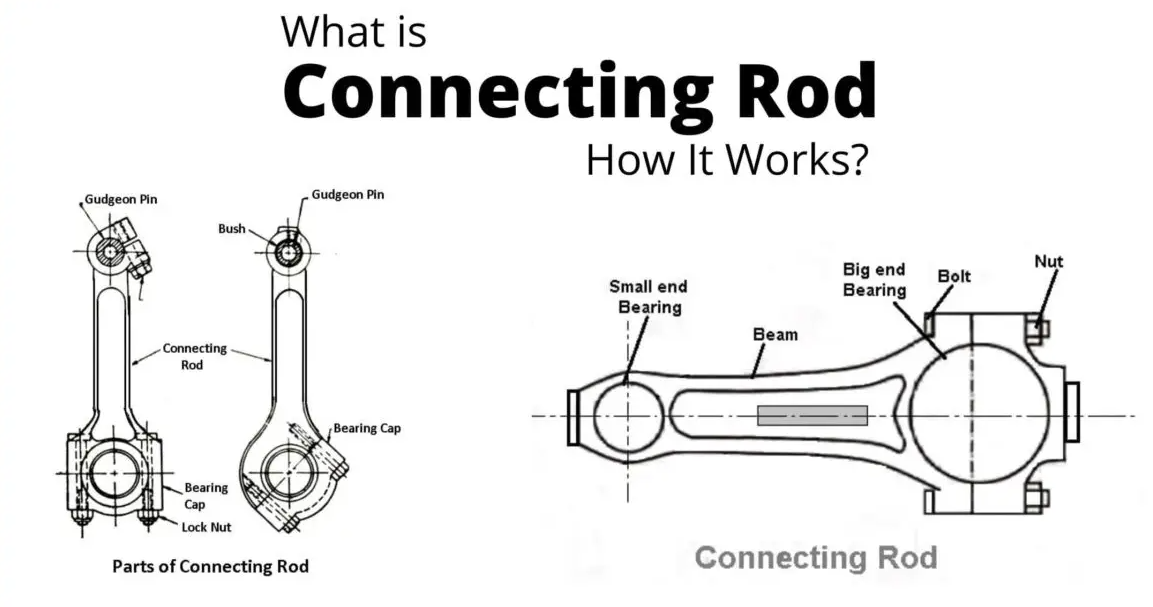

Definition and Role of a Connecting Rod

The connecting rod is another critical engine component, serving as the link between the piston and the crankshaft.

Connecting rods must be strong enough to withstand high-pressure combustion and the tensile and compressive stresses associated with the piston’s movement.

Detailed Analysis: The Role of Connecting Rods in Piston Function

Once we understand the basic definitions and roles of the piston and the connecting rod, it’s necessary to dig deeper into the connecting rod’s functionality and its crucial role in a piston’s operation.

Mechanical Force Transmission

The connecting rod plays a pivotal role in transmitting the mechanical force from the piston to the crankshaft. When the air-fuel mixture in the combustion chamber ignites, it generates significant force, pushing the piston down.

Converting Reciprocating Motion into Rotational Motion

One of the most significant roles of the connecting rod is to convert the piston’s reciprocating (up and down) motion into the rotational motion of the crankshaft. This conversion is critical for the operation of the engine, as the vehicle’s wheels need rotational movement to propel the car forward. Without the connecting rod, the reciprocating motion of the piston would not result in useful work.

Ensuring Smooth Operation of the Engine

In addition to transmitting force and converting motion, the connecting rod also plays an essential role in maintaining the smooth operation of the engine. By efficiently transferring the piston’s motion, the connecting rod ensures that the crankshaft rotates smoothly, avoiding damaging vibrations that could harm the engine. Moreover, modern connecting rods often have features such as oil passages for lubrication, further promoting smooth operation and reducing wear and tear.

Influence on Engine’s Speed and Power

The design and condition of the connecting rod can significantly influence an engine’s speed and power. A well-designed, well-maintained connecting rod can transfer force more efficiently, leading to better engine performance. Conversely, a damaged or poorly designed connecting rod can decrease engine power and speed, leading to inefficient fuel consumption and potentially causing further engine damage.

Design and Construction of Connecting Rods

The design and construction of connecting rods significantly influence the performance and longevity of an engine. From the material selection to the advanced design features, every aspect plays a crucial role in their overall functionality and efficiency.

Material Selection and Properties

Two of the most common materials used are steel and aluminum.

However, they are heavier than their aluminum counterparts, potentially affecting engine balance and responsiveness.

On the other hand, aluminum connecting rods are lighter, providing less rotational mass and contributing to a more responsive engine. They also have better thermal conductivity, which helps dissipate heat. But they may not be as durable as steel rods under extreme stress, limiting their use to specific applications.

Impact of Design on Functionality and Efficiency

The design of the connecting rod greatly impacts the engine’s functionality and efficiency. For example, the length of the rod affects the piston’s dwell time at top dead center and bottom dead center, influencing the engine’s torque and power output. Moreover, the shape of the rod, the placement of the oil passages, and the design of the rod ends can all have substantial impacts on the engine’s performance and efficiency.

Advanced Design Features for Optimal Performance

Modern connecting rods often come with advanced design features to enhance their performance. These features may include micro-polished surfaces to reduce friction, specialized heat treatments for increased strength and durability, and optimized weight distribution for improved balance and reduced vibration.

Computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies have made it possible to achieve high precision and uniformity in connecting rod production, leading to better engine performance and longer component life.

The Connecting Rod-Piston Assembly Process

Assembling the piston and connecting rod is a critical process in engine building. It requires meticulous preparation, careful assembly, and the ability to overcome potential challenges.

Preparing the Parts

Before starting the assembly process, all parts must be thoroughly inspected and cleaned. The piston and connecting rod should be free of dirt, rust, and any manufacturing residues.

It’s also important to check for any physical damage or defects in the parts. Using a damaged or flawed component can lead to engine failure. Any sign of damage or abnormality is a cue for part replacement.

This step can help prevent damage caused by dry starts when the engine is first operated.

Process of Assembly

The assembly process involves several steps. First, the piston pin bore and the small end of the connecting rod are heated to expand their size. Next, the piston pin is inserted through the piston pin bore and the connecting rod’s small end, joining the two parts together.

After that, snap rings are installed at both ends of the piston pin bore to secure the piston pin in place. It is essential to make sure that the snap rings are fully seated in their grooves to prevent them from coming loose during engine operation.

Finally, the connecting rod big end is attached to the crankshaft, completing the piston-connecting rod assembly.

Potential Challenges and How to Overcome Them

The piston-connecting rod assembly process can present several challenges. One of the most common is misalignment of the piston and the connecting rod, which can lead to uneven wear and possible engine damage. Using precision tools and following proper assembly procedures can help prevent this issue.

Another potential challenge is the installation of the snap rings. If not properly installed, they can come loose during engine operation, leading to catastrophic engine failure.

With a good understanding of the assembly process and potential challenges, one can ensure a successful piston-connecting rod assembly and optimal engine performance.

Maintenance and Troubleshooting of Pistons and Connecting Rods

Proper maintenance and prompt troubleshooting of pistons and connecting rods are crucial for the longevity of an engine. By recognizing the signs of a failing connecting rod and knowing the essential maintenance tips, one can prevent significant engine damage and costly repairs.

Signs of a Damaged or Failing Connecting Rod

There are several signs that might indicate a problem with the connecting rod. One of the most common is a knocking noise coming from the engine. This noise usually indicates that the rod has loosened and is knocking against other parts inside the engine.

These symptoms might indicate a problem with the piston-connecting rod mechanism.

Visible smoke from the exhaust can also indicate issues.

Maintenance Tips for Longevity

Regular maintenance is vital for the longevity of pistons and connecting rods. This maintenance might include regular oil changes to ensure proper lubrication and minimize wear and tear, routine inspections for any visible signs of damage or wear, and proper engine operation to avoid over-revving, which can lead to excessive stress on the connecting rod.

Additionally, using high-quality parts during repairs or replacements can significantly extend the life of the piston-connecting rod mechanism.

Common Problems and Possible Solutions

Common problems with pistons and connecting rods might include damage due to overheating, oil contamination, or mechanical stresses.

In the case of overheating or contamination, the solution might involve improving the cooling system or enhancing the oil filtration.

For mechanical stress damage, one possible solution might be to replace the damaged parts.

By understanding the common problems and their possible solutions, one can effectively troubleshoot and maintain the piston-connecting rod mechanism, ensuring optimal engine performance and longevity.

Referensi

- Piston

- Connecting rod

- Crankshaft

- Internal combustion engine

- Reciprocating engine

- Four-stroke engine

- Two-stroke engine