crankshaft is a critical component of an engine that converts the linear motion of the pistons into rotary motion.

This rotary motion then drives the vehicle’s transmission and ultimately propels the wheels.

The crankshaft, with its intricate design and construction, significantly influences the engine’s efficiency, performance, and longevity.

Understanding Basic Engine Mechanics

Understanding the mechanics of an engine is crucial to appreciate the function of the crankshaft. Engines, regardless of the type, are complex assemblies with many integral components working together to convert fuel into mechanical power.

Engine Components: An Overview

An internal combustion engine comprises several major components that interact to deliver power. Here’s a brief overview of some of the main parts:

- Cylinder: The cylinder is the space in which the piston moves up and down. The number of cylinders in an engine can vary.

- Piston: The piston is a cylindrical component that moves up and down inside the cylinder.

- Spark Plug: Ignites the air-fuel mixture inside the cylinder at the right moment.

- Valves: Intake and exhaust valves allow the air-fuel mixture in and the exhaust gases out.

- Crankshaft: The crankshaft converts the linear motion of the piston into rotational motion.

- Camshaft: Controls the opening and closing of the intake and exhaust valves.

- Connecting Rod: Links the piston to the crankshaft, transmitting the force from the piston to the crankshaft.

- Sump: The bottom part of the engine where oil collects.

These are just some of the essential components of an engine. Each of them plays a vital role in the engine’s functioning.

Understanding Engine Cycles

An internal combustion engine works on a cycle, commonly known as the four-stroke cycle or Otto cycle. These four strokes are intake, compression, combustion (or power), and exhaust. Understanding these cycles is key to comprehending how an engine, and particularly a crankshaft, operates.

- Intake Stroke: The piston moves down the cylinder while the intake valve opens to allow a mixture of air and fuel into the cylinder.

- Compression Stroke: The intake valve closes, and the piston moves up the cylinder, compressing the air-fuel mixture.

- Combustion Stroke: The spark plug ignites the compressed air-fuel mixture, causing an explosion that pushes the piston down the cylinder.

- Exhaust Stroke: The exhaust valve opens, and the piston moves up the cylinder, pushing the exhaust gases out of the cylinder.

This process repeats many times per minute, with the crankshaft playing a pivotal role in converting the up-and-down movement of the piston into the rotational motion needed to drive the wheels of a vehicle.

Each part of the engine and each stage of the cycle is crucial to the engine’s overall operation and efficiency. Understanding these basic mechanics helps one appreciate the complex symphony that is an internal combustion engine.

What is a Crankshaft?

A crankshaft is an essential part of an internal combustion engine that converts reciprocating linear piston motion into rotation. This component’s understanding will allow us to see its crucial role in making an engine function efficiently.

Definition of Crankshaft

A crankshaft is a mechanical part able to perform a conversion between reciprocating motion and rotational motion.The crankshaft contains one or more large sections known as crankpins, to which the connecting rods from each piston attach.

Parts of a Crankshaft

The crankshaft is made up of several key parts:

- Main Journals: These are the points where the crankshaft rotates on the engine block.

- Counterweights: These are designed to offset the weight of the rods and pistons. They reduce vibration and make the engine run smoothly.

- Crankshaft pulley: This is located at the front end of the crankshaft, which transfers motion to other engine components via belts.

- Flywheel: At the rear end of the crankshaft, the flywheel helps provide continuous rotation and smooth out the power delivery.

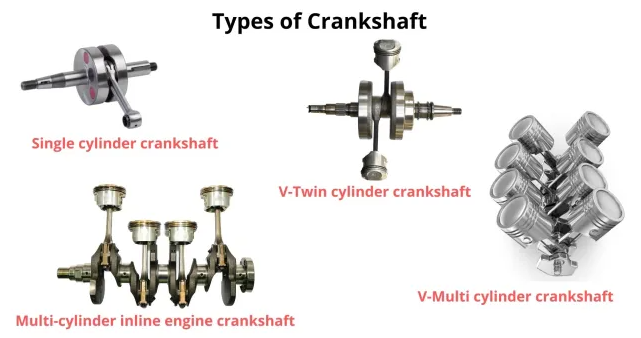

Types of Crankshafts

There are primarily three types of crankshafts, each with their own unique properties:

- Cast Crankshaft: These are manufactured by pouring molten iron or steel into a mold and are used in most mass-produced engines due to their lower production cost.

- Forged Crankshaft: These are made by hammering a roughly shaped bar of heated steel into the final shape. They are stronger than cast crankshafts but are more expensive to manufacture.

- Billet Crankshaft: Billet crankshafts are machined from a solid bar of steel. While they are the most expensive, they also have the highest tensile strength and can be custom made for specific applications.

Understanding the structure and types of crankshafts is vital to grasp how different engines are designed and what their advantages or disadvantages might be.

Role of a Crankshaft in an Engine

The crankshaft is one of the primary components of an engine, playing a critical role in converting the reciprocating motion from the pistons into rotational motion that ultimately drives the vehicle. It also plays a significant part in the distribution of power throughout the engine.

Conversion of Linear to Rotary Motion

A primary function of the crankshaft is to convert the linear motion of the pistons into rotary motion. As the pistons move up and down in the cylinders, they push against the crankpins on the crankshaft.This conversion process is crucial for the operation of the internal combustion engine.

Distribution of Engine Power

The crankshaft also plays a vital role in distributing the power produced by the engine. When the air-fuel mixture in an engine cylinder combusts, it generates force that pushes the piston.Through this rotational motion, the crankshaft transmits this power to the various systems in the vehicle, including the transmission, drive shaft, and ultimately the wheels.

The strength, design, and construction of the crankshaft directly impact the engine’s efficiency and power. Thus, it is one of the most critical components in any engine design. Its design and manufacturing quality can significantly influence a vehicle’s performance and reliability.

How does a Crankshaft Work?

The operation of a crankshaft is an intricate process that lies at the heart of how an engine functions. By translating the linear movement of the pistons into rotational motion, the crankshaft plays a pivotal role in the workings of a vehicle.

The Working Principle of a Crankshaft

The crankshaft operates on a simple yet effective mechanical principle.

Detailed Explanation of the Crankshaft’s Function

The crankshaft, via its connection with the pistons, plays a central role in the four-stroke engine cycle.

- Intake Stroke: As the piston moves down, the crankshaft rotates, pulling air and fuel into the combustion chamber.

- Compression Stroke: The piston moves up, and the crankshaft continues to rotate, compressing the air-fuel mixture.

- Combustion Stroke: The air-fuel mixture ignites, driving the piston down and rotating the crankshaft.

- Exhaust Stroke: The piston moves back up to expel the combustion gases, and the crankshaft completes its rotation.

Furthermore, the crankshaft also interacts with other engine components. It connects with the flywheel, which helps maintain smooth engine operation by reducing vibration and storing rotational energy. The front end of the crankshaft often drives additional components via a belt or chain, such as the alternator, water pump, and power steering pump.

Understanding how a crankshaft works allows us to appreciate the ingenious engineering behind the internal combustion engine and the essential role of this pivotal component in making vehicles move.

Significance of a Crankshaft in Engine Efficiency

The crankshaft’s role extends beyond converting linear motion to rotary motion. Its design, material, and manufacturing process significantly influence engine efficiency, performance, and longevity.

Influence on Fuel Efficiency

The crankshaft‘s design and weight significantly affect the engine’s fuel efficiency. A lighter crankshaft reduces the engine’s overall weight, which can lead to increased fuel efficiency. Moreover, a well-balanced crankshaft reduces vibration and energy loss, resulting in more efficient operation and better fuel economy.

Impact on Engine Performance

For instance, crankshafts with more counterweights can reduce engine vibration, leading to smoother operation and better overall performance. In high-performance engines, the crankshaft’s strength is critical as it needs to withstand higher combustion pressures. The material, design, and manufacturing quality of a crankshaft play a significant role in ensuring it can handle these pressures without failing.

Crankshaft and Engine Longevity

A well-made crankshaft also contributes to the engine’s longevity. The use of high-quality materials in the crankshaft can resist wear and tear, resulting in a longer-lasting engine. Regular maintenance, including proper lubrication, is also crucial in preventing premature wear of the crankshaft and other engine components. It’s also worth noting that a defective or worn crankshaft can cause serious engine damage, underscoring the component’s importance in ensuring the engine’s long life.

Problems and Solutions related to Crankshafts

Just like any mechanical component, the crankshaft can develop issues over time due to various reasons such as regular wear and tear, lack of maintenance, or manufacturing defects. Understanding these issues and their corresponding solutions is essential for maintaining the longevity of an engine.

Common Crankshaft Problems

Several problems could arise concerning the crankshaft:

- Wear and Tear: Over time, the journals on the crankshaft may wear down due to friction, potentially leading to reduced engine performance and efficiency.

- Crankshaft Deflection: This happens when the shaft bends under load, which can lead to vibration, bearing wear, and potential engine damage.

- Cracks or Breaks: High-performance engines or those under significant stress can develop cracks or even break in the crankshaft.

- Imbalance: An unbalanced crankshaft can lead to engine vibration, wear in the engine bearings, and other potential problems.

Repair and Maintenance of Crankshafts

Solutions to these problems include:

- Regular Inspection and Maintenance: Regularly checking the crankshaft and associated components can help identify issues early before they cause more significant damage.

- Balancing: If the crankshaft is unbalanced, it may need to be balanced professionally to prevent vibrations and potential engine damage.

- Grinding and Polishing: If the crankshaft journals are worn or damaged, they can often be ground down to a smaller size and then polished to create a smooth surface.

- Replacement: In severe cases, such as deep cracks or breaks, the entire crankshaft may need to be replaced.

Regular maintenance and timely repair of the crankshaft are crucial to ensure the smooth operation and long life of the engine.

Crankshafts in Different Types of Engines

While the basic function of a crankshaft remains the same across different engine types, there can be variations in design, material, and manufacturing process based on the specific requirements of the engine.

Crankshafts in Gasoline Engines

Gasoline engines, typically lighter than their diesel counterparts, usually employ crankshafts made from cast iron or forged steel.

Due to the lower compression ratio and combustion pressure of gasoline engines, the crankshafts in these engines don’t have to be as robust as those in diesel engines.

Crankshafts in Diesel Engines

Diesel engines, known for their high compression ratios and substantial combustion pressures, require more robust and sturdy crankshafts. Therefore, these engines typically employ crankshafts made from forged steel, which provides the necessary strength and durability to withstand the intense forces.

Moreover, diesel crankshafts often feature larger bearing surfaces to distribute the increased load evenly. The weight of a diesel engine crankshaft is also typically more than that of a gasoline engine, contributing to a generally higher engine weight.

Crankshafts in Hybrid Engines

In hybrid engines, the focus is more on efficiency and reducing overall vehicle weight to maximize fuel economy.

Advances in technology have led to the development of composite materials that can provide the necessary strength while significantly reducing weight.

In conclusion, while the role of a crankshaft remains consistent across different engine types, its design and construction can vary significantly based on the specific requirements and characteristics of the engine in question.