The primary parts of a crankshaft include:Main Journals: These serve as the axis of rotation for the crankshaft.

Connecting Rod Journals (Crankpins): Offset from the main journals, these connect with the connecting rods, transferring force from the pistons.

Counterweights: These balance the weight of the connecting rods and pistons.

Crankshaft Web: This connects the crankpins and main journals.

Crankshaft Flange: Usually located at the rear, this is typically used to attach the flywheel or a flexplate.

Introduction

The purpose of this article is to delve into the fascinating world of one of the most critical components of an engine, the crankshaft. This critical engine component transforms the linear motion of pistons into rotational motion that drives the wheels of a vehicle.

Brief Overview of the Crankshaft

A crankshaft, often abbreviated as ‘crank’, is an essential part of an engine. Its primary role is to convert the reciprocating linear motion of the pistons into rotational motion, which is necessary to power the vehicle. The crankshaft resides inside the engine block, connecting with other components like connecting rods and bearings to facilitate this transformation of motion.

Importance and Role of a Crankshaft in an Engine

The crankshaft serves as the backbone of an engine. It takes the force from the pistons, turns it into a torque through the connecting rods, and then transmits this power to the wheels of the vehicle. Without the crankshaft’s continuous operation, a vehicle’s mobility would be severely impacted, highlighting the essential role of the crankshaft.

Understanding Crankshafts

To appreciate the complexity and beauty of crankshafts, we need to delve deeper into how they function, their role in different types of engines, and the fundamental principles behind their operation.

Basic Functions of a Crankshaft

A crankshaft serves multiple purposes within an engine. Its most crucial role is to transform linear piston motion into rotational motion. Furthermore, the crankshaft balances the forces within the engine, provides attachment points for the flywheel and clutch or torque converter, and houses passages for oil.

Crankshaft in Internal Combustion Engine

In an internal combustion engine, the crankshaft plays a crucial role in converting the explosive energy generated by the combustion process into useful work that propels the vehicle. It also ensures the smooth operation of the engine by balancing out vibrations and forces.

Crankshaft in Two-stroke and Four-stroke Engines

While the fundamental function of a crankshaft remains the same across engine types, the operating principles slightly vary between two-stroke and four-stroke engines. In both cases, the crankshaft’s job is to convert piston movement into rotational motion, but the specific method and the engine’s power cycles influence the crankshaft’s design and operation.

Basic Functions of a Crankshaft

The crankshaft, a vital part of the engine, serves multiple roles to ensure the smooth and efficient operation of a vehicle. Here are some of its basic functions:

| Function | Description |

|---|---|

| Motion Conversion | The crankshaft converts the linear motion of the pistons into rotational motion, providing the force that propels the vehicle. |

| Balancing Forces | The crankshaft helps balance the forces generated within the engine, reducing vibrations and promoting smooth operation. |

| Attachment Points | The crankshaft provides points of attachment for other crucial engine components, such as the flywheel and the clutch or torque converter. |

| Oil Passage | The crankshaft often includes passages for oil, assisting in the lubrication and cooling of the engine. |

Crankshaft in Internal Combustion Engine

The internal combustion engine is a complex system, and the crankshaft plays a critical role within it.

Energy Conversion

The fundamental role of a crankshaft in an internal combustion engine is to convert the energy produced during the combustion process into useful work that propels the vehicle. It takes the linear motion resulting from the explosion in the combustion chamber and transforms it into rotational motion.

Smooth Operation

In addition to power conversion, the crankshaft balances vibrations and forces generated during the combustion process. This role is critical to the smooth operation and longevity of the engine.

Crankshaft in Two-stroke and Four-stroke Engines

The basic function of the crankshaft remains the same across different types of engines. However, there are variations in the design and operation between two-stroke and four-stroke engines.

Two-stroke Engines

In a two-stroke engine, the crankshaft completes one full revolution (360 degrees) for each power stroke. It allows for a simpler and lighter design compared to a four-stroke engine, although two-stroke engines typically produce more emissions.

Four-stroke Engines

In contrast, a four-stroke engine requires two full revolutions (720 degrees) of the crankshaft for each power stroke. This results in more controlled combustion and less pollution but comes with a slightly more complex design.

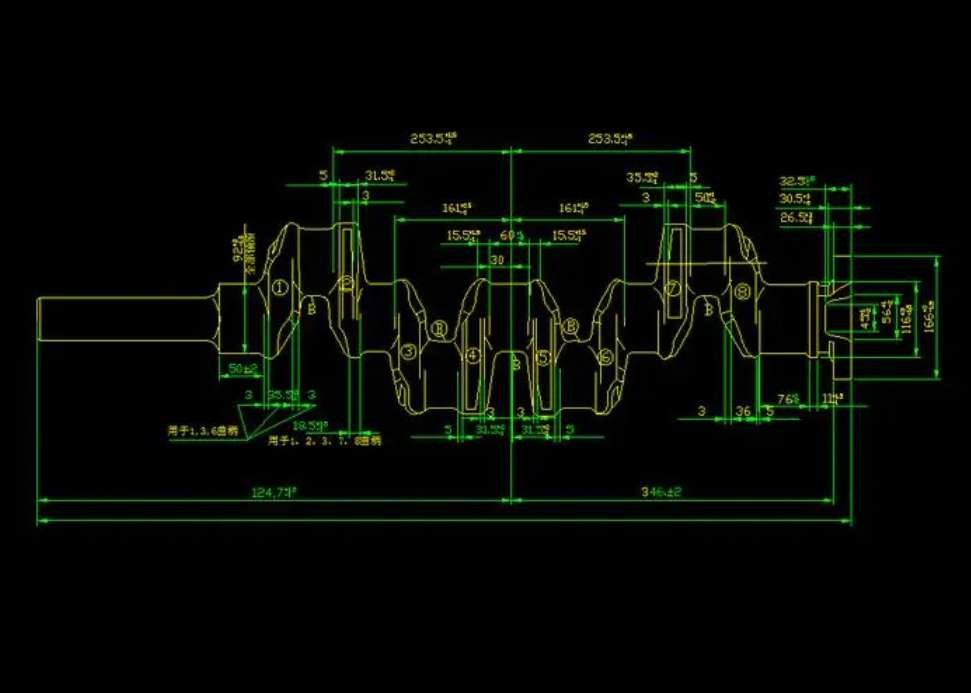

Parts of a Crankshaft

The crankshaft is a complex piece of machinery composed of several key parts, each playing a crucial role in its function. Understanding these individual components can provide a better understanding of how the crankshaft works as a whole.

Main Journals

The main journals are an integral part of a crankshaft. They are the portions that rest on the engine block and support the crankshaft within the engine. Essentially, they are the parts of the crankshaft that rotate within the bearings, allowing for the necessary rotation while also providing stability.

The number of main journals can vary depending on the type and design of the engine, but each one is critical in distributing the forces created by the pistons and ensuring the crankshaft rotates smoothly and efficiently.

Connecting Rod Journals (or Crankpins)

Connecting rod journals, also known as crankpins, are the areas on the crankshaft where the connecting rods attach. Each connecting rod journal pairs with a piston in the engine.

As the piston moves up and down, the connecting rod transfers that motion to the crankpin, which then uses that force to rotate the crankshaft. This process is the fundamental method by which the linear motion of the pistons gets converted into rotational motion.

The size and location of the crankpins are critical to the balance and overall operation of the crankshaft and engine. Poorly designed or misaligned crankpins can lead to engine vibration, excessive wear, and potential engine failure.

Counterweights

Counterweights are a crucial part of a crankshaft. Their main role is to balance the reciprocating forces generated by the movement of the pistons and the connecting rods. Without them, the crankshaft and, by extension, the engine would suffer from excessive vibration, affecting performance and leading to premature wear.

In a well-manufactured crankshaft, like those produced by FDautoparts, the counterweights are strategically placed opposite the crankpins. They are typically made from the same material as the crankshaft to ensure consistency in thermal expansion and overall balance.

Thrust Bearings Surfaces

Thrust bearing surfaces, also known as thrust faces, help manage the axial or longitudinal forces applied to the crankshaft. During engine operation, various components such as the clutch and gearbox can exert axial forces on the crankshaft. These surfaces work to control and resist these forces, ensuring the crankshaft only rotates around its axis and doesn’t move back and forth.

FDautoparts ensures that their crankshafts are designed with high-quality thrust bearings surfaces to offer excellent performance and longevity.

Crankshaft Pulley

The crankshaft pulley, also known as the harmonic balance wheel, serves two primary purposes. It drives various engine accessories like the alternator, power steering pump, air conditioning compressor, and water pump via the serpentine belt. Additionally, it helps to balance and dampen vibrations in the crankshaft.

FDautoparts’ crankshaft pulleys are meticulously crafted to guarantee optimal performance and to extend the life of the crankshaft and other related components.

Flywheel/Flex Plate

The flywheel or flex plate connects to one end of the crankshaft, serving two main functions. In manual transmissions, the flywheel provides a mounting surface for the clutch assembly, and in automatic transmissions, the flex plate connects the crankshaft to the torque converter.

Furthermore, the flywheel/flex plate plays a crucial role in smoothing out the power delivery by maintaining rotational inertia. It also provides a toothed outer ring that the starter motor can engage to crank the engine during the starting process. With FDautoparts, you can trust that their flywheels and flex plates are designed and manufactured to the highest standards for reliable performance.

Oil Holes

Oil holes in a crankshaft, often referred to as oil passages, play a significant role in the lubrication and cooling of the crankshaft and related components. These holes allow motor oil to flow freely from the main journals to the rod journals (or crankpins).

The lubrication provided by the oil flow through these passages helps reduce friction, heat, and wear between the moving parts. It allows the crankshaft to operate smoothly and efficiently, thereby prolonging its lifespan and the engine’s overall lifespan.

Materials and Manufacturing

The materials used in crankshaft production, and the manufacturing process itself, significantly impact the quality, durability, and performance of the crankshaft.

Common Materials Used for Crankshafts

Crankshafts are typically made from steel or cast iron, with the choice of material depending on the specific application.

- Steel crankshafts are highly durable and can withstand high-performance demands, making them suitable for racing or high-performance engines.

- Cast iron crankshafts are generally cheaper and easier to produce, making them a common choice for many standard production engines.

Process of Crankshaft Manufacturing

Crankshaft manufacturing involves several steps, including forging or casting the raw material, heat treating to enhance hardness and durability, machining to achieve precise dimensions and surface finishes, and finally, balancing to ensure smooth operation. This manufacturing process requires precision and attention to detail to create a product capable of withstanding the intense operating conditions inside an engine.

Common Materials Used for Crankshafts

Different materials are used to manufacture crankshafts, each having specific properties that make them more suitable for certain applications. Here’s a summary in table form:

| Material | Advantages | Disadvantages | Common Applications |

|---|---|---|---|

| Steel | High strength, durable, can withstand high-performance demands | More expensive, more complex manufacturing process | High-performance engines, racing engines |

| Cast Iron | Cheaper, easier to produce | Not as strong or durable as steel | Standard production engines |

Process of Crankshaft Manufacturing

Crankshaft manufacturing is a complex process that requires high precision and extensive expertise. The key steps include:

- Casting or Forging: The raw material (usually steel or cast iron) is shaped into a rough approximation of the crankshaft’s final shape.

- Heat Treating: The forged or cast material is heat-treated to enhance its hardness and durability, improving the crankshaft’s strength.

- Machining: The heat-treated material is then machined to achieve precise dimensions and surface finishes, resulting in the final crankshaft shape.

- Balancing: The finished crankshaft is balanced to ensure smooth operation when installed in an engine.

Types of Crankshafts

There are several types of crankshafts, categorized based on various characteristics such as the design of the crank throws and the number of cylinders they’re designed for. Some common types include:

- Monolithic Crankshaft: These are made from a single piece of material, usually through forging or casting. They are robust and can handle a high degree of stress.

- Assembled or Built-up Crankshaft: These are made from multiple pieces joined together. They are commonly used in large engines where a monolithic design would be impractical or too heavy.

- Flat Plane vs Cross Plane Crankshaft: This categorization is based on the crank pin arrangement. Flat plane crankshafts are often found in high-performance vehicles due to their high RPM potential, while cross plane crankshafts are common in standard V8 engines for their smooth operation and low vibration.

Monolithic Crankshaft

Monolithic crankshafts are forged or cast as a single piece of material, usually steel or cast iron. The monolithic design enhances the strength and durability of the crankshaft, allowing it to withstand high levels of stress. This type of crankshaft is commonly used in automobile engines and other small to medium-sized engines.

Assembled Crankshaft

Assembled or built-up crankshafts are constructed from multiple pieces that are joined together. This design is generally used in large engines where a monolithic design would be impractical or too heavy. The assembled crankshaft allows for easier manufacturing and replacement of individual components, potentially reducing maintenance costs.

Comparing the Two Types

Comparing these two types of crankshafts:

| Crankshaft Type | Advantages | Disadvantages |

|---|---|---|

| Monolithic Crankshaft | High strength and durability, can withstand high stress levels | More complex manufacturing process, potentially higher costs |

| Assembled Crankshaft | Easier manufacturing and maintenance, suitable for large engines | Lower overall strength compared to monolithic design |

Crankshaft Design and Analysis

The design and analysis of a crankshaft are crucial steps in engine development and can significantly impact the engine’s performance and lifespan. Crankshaft design involves determining the optimal size, shape, and positioning of components, such as the journals and counterweights, to achieve the best balance and operational efficiency.

During the analysis phase, various factors like stress distribution, torsional vibrations, and load variations are studied to ensure the crankshaft can withstand the operating conditions inside an engine. Nowadays, advanced software tools are often used in the design and analysis of crankshafts, enabling engineers to perform detailed simulations and make necessary adjustments before the manufacturing process begins.

Design Considerations for Crankshafts

When designing a crankshaft, several considerations come into play to ensure optimal performance and longevity. Here are some of the key considerations:

- Material Selection: As previously mentioned, crankshafts are typically made from steel or cast iron. The choice of material can have a significant impact on the crankshaft’s strength, durability, and cost.

- Geometry and Balance: The shape and balance of the crankshaft also play a crucial role in its performance. The placement of the main journals, rod journals (or crankpins), and counterweights needs to be carefully calculated to ensure smooth operation and minimal vibration.

- Lubrication: The design of oil passages or oil holes within the crankshaft is also essential. Proper lubrication helps reduce friction, heat, and wear, prolonging the lifespan of the crankshaft and the engine.

At FDautoparts, these design considerations are given utmost importance to ensure the highest quality of their crankshafts.

Load and Stress Analysis on Crankshafts

Load and stress analysis is a critical aspect of crankshaft design. This involves studying the forces and stresses the crankshaft will be subjected to during operation.

Crankshafts undergo several types of stresses, including bending, torsion, and shear stress. By analyzing these stresses, engineers can design crankshafts that can withstand these forces without failure. FDautoparts uses state-of-the-art software tools for precise load and stress analysis, ensuring their crankshafts are capable of withstanding intense operating conditions.

Common Crankshaft Problems and Solutions

Crankshafts can encounter several issues over their lifespan, often due to wear, poor maintenance, or manufacturing defects. Some common problems include:

- Worn Journals: Over time, the main and rod journals can wear down due to friction, leading to engine vibration and potential failure. Regular oil changes and ensuring proper lubrication can help prevent this.

- Cracked or Broken Crankshafts: These are usually due to excessive stress or manufacturing defects. Choosing high-quality crankshafts like those from FDautoparts can help avoid this issue.

- Out of Balance Crankshaft: This can cause excessive engine vibration and premature wear. Crankshafts should be professionally balanced to prevent this problem.

These problems can often be solved or prevented through regular maintenance, careful use, and choosing high-quality parts from reliable manufacturers like FDautoparts.

Wear and Tear

Just like any mechanical component, crankshafts are subject to wear and tear over time. The most common wear occurs on the main and rod journals due to the continuous friction between the crankshaft and the bearings. This can lead to a decrease in engine performance and potentially severe engine damage if not addressed.

It’s crucial to perform regular maintenance, including oil changes and inspections, to minimize wear and extend the lifespan of the crankshaft.

Crankshaft Misalignment

Crankshaft misalignment is a condition where the crankshaft is not correctly aligned within the engine block. This can occur due to various reasons, such as improper installation, bearing failure, or the engine block warping due to excessive heat.

Misalignment can cause uneven wear on the bearings, increased vibration, and reduced engine efficiency. To prevent this, it’s essential to ensure that the crankshaft is correctly installed and that the engine block is in good condition.

Crankshaft Failure: Causes and Symptoms

Crankshaft failure can occur due to several reasons, including excessive wear, inadequate lubrication, excessive load, or manufacturing defects. Some common symptoms of crankshaft failure include:

- Increased Vibration: This could be a sign of a worn or out-of-balance crankshaft.

- Engine Knocking Noise: This might indicate a bearing failure, which could lead to crankshaft damage if not addressed.

- Decreased Engine Performance: This could be a result of various issues, including crankshaft wear or damage.

Solutions and Maintenance Tips

Proper maintenance and usage can significantly extend the lifespan of a crankshaft and prevent many common issues. Here are some general tips:

- Regular Oil Changes: Fresh oil provides better lubrication and helps reduce wear on the crankshaft journals.

- Proper Engine Usage: Avoiding extreme loads can help reduce the stress on the crankshaft and other engine components.

- Regular Inspections: Regularly inspecting the crankshaft and related components can help identify and address issues before they lead to failure.

- High-Quality Parts: Using high-quality parts, like those provided by FDautoparts, can help ensure durability and longevity.

Remember, preventive maintenance is always better (and often cheaper) than dealing with a failure.

Conclusion

Crankshaft Design Innovations

Crankshaft design has evolved significantly over the years and continues to do so. Innovations have primarily focused on improving efficiency, reducing weight, and enhancing durability. Advances in material science, machining processes, and computer simulations have allowed for more robust and lightweight crankshafts. This has been achieved by exploiting composite materials, employing sophisticated casting techniques, and optimizing the geometry of crankshafts.

Summary

The Evolution of Crankshaft Design

In summary, the crankshaft, a key part of the internal combustion engine, has seen a lot of development over the years. It has evolved from a simple mechanical part into a high-tech component, with improvements in materials, design, and manufacturing techniques. These advancements have made the crankshaft more efficient, lightweight, and durable, contributing to improved engine performance and fuel efficiency.

Future Trends in Crankshaft Design

Material Innovations

Future trends in crankshaft design will likely focus on further material advancements. Current research shows a lot of promise for materials like composite carbon fiber and metal matrix composites. These materials offer superior strength-to-weight ratios compared to traditional crankshaft materials, potentially leading to even more efficient engines.

Design and Manufacturing Improvements

Another promising area is in the realm of design and manufacturing. More precise and advanced manufacturing techniques like additive manufacturing or 3D printing may pave the way for highly optimized crankshaft designs that were previously unattainable with traditional methods. This could result in further improvements in engine performance and efficiency.