The price of a crankshaft can vary significantly based on several factors, including the material it’s made from, the type of engine it’s designed for, the manufacturing process used to make it, and the brand. In general, the cost for a new crankshaft ranges from around $150 to over $1500.More specifically, for smaller engines, like a 4-cylinder engine, you might expect to pay in the range of $150 to $500. For a larger V6 engine, the cost can be between $300 to $800, while for a V8 engine, you might be looking at anywhere from $500 to over $1500. Please note that these prices are general estimates and actual prices can vary.

Introduction

Definition of a Crankshaft

A crankshaft is a critical component in an internal combustion engine. It converts the reciprocating linear motion of the pistons into rotational motion which is ultimately used to power the vehicle or machine.

Function of a Crankshaft in an Engine

In an engine, the crankshaft plays a vital role. It receives the force from the combustion process in the form of piston movement, converts it into a rotary motion which then drives the wheels of the vehicle or other equipment in the machine.

Understanding the Crankshaft

Materials Used in Crankshaft Production

Crankshafts are typically made from steel or iron. High-performance crankshafts, such as those used in racing engines, may be made of alloy steels or even exotic materials like titanium. The material choice largely depends on the expected stresses and the cost-efficiency.

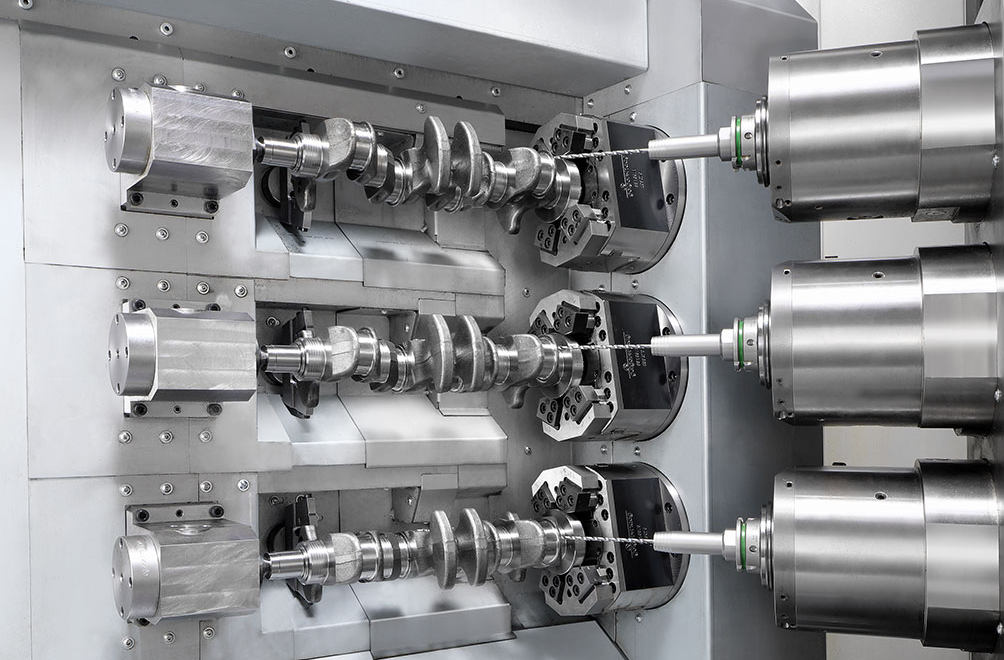

Manufacturing Process of Crankshafts

The production of a crankshaft usually involves processes like forging, casting, machining, heat treatment, and finishing. Forging results in a stronger crankshaft, but it is more expensive compared to casting. After the initial creation, the crankshaft undergoes precision machining to ensure the proper fit and finish.

Different Types of Crankshafts

There are mainly two types of crankshafts – flat plane and cross plane. Flat plane crankshafts, typically found in high-performance and racing engines, are lighter and allow higher RPMs. Cross plane crankshafts, commonly found in V6 and V8 engines, offer smoother operation at lower RPMs and are less prone to vibration. Each type has its own advantages and trade-offs, and the choice depends on the specific application of the engine.

Material Costs

One of the significant factors affecting the cost of a crankshaft is the material used in its construction. Common materials include cast iron and steel, with higher-end crankshafts sometimes made from alloy steels or even titanium. The choice of material significantly impacts the cost, as some materials are more expensive due to their superior strength and durability. For example, a crankshaft made for FEDA‘s high-performance engines might use more costly materials to ensure longevity and resist wear under extreme conditions.

Production Complexity

The complexity of the manufacturing process also plays a role in the final price of a crankshaft. Forging and casting are two common methods of crankshaft production, with forging usually being more expensive due to the higher strength and quality it offers. Additionally, the machining and finishing processes can add to the complexity and cost.

Brand and Quality

Brands, such as FEDA, that are known for high-quality components, often price their crankshafts higher due to the reputation and trust they’ve built in the market. Quality assurance, rigorous testing, and customer service are factors that can increase the cost.

Type of Engine

The type of engine also determines the cost of a crankshaft. Larger, more complex engines, like V8s, require larger, more robust crankshafts, which are typically more expensive than those for smaller engines. Also, special types of engines, such as those for racing or luxury vehicles, may require custom-made or specially designed crankshafts, which can increase the cost.

Market Demand and Supply

Like any product, the principles of demand and supply also influence the cost of a crankshaft. If there’s a surge in demand for certain types of crankshafts, or if there’s a shortage of the materials needed to make them, prices can rise. Conversely, if demand falls or there’s an oversupply, prices might decrease.

General Cost Estimates

The cost of a crankshaft can vary significantly based on the factors we’ve discussed earlier. Generally, you can expect to pay anywhere from $150 to over $1500 for a new crankshaft. Lower-end crankshafts are typically made of less expensive materials and may not be as durable or perform as well as higher-end versions.

Price Comparisons by Engine Type

Different engine types require different types of crankshafts, which can lead to variations in price. For instance, a crankshaft for a small 4-cylinder engine will generally cost less than one for a larger V8 engine.

Here’s a general price comparison table for reference:

| Engine Type | Average Crankshaft Price |

|---|---|

| 4-Cylinder | $150 – $500 |

| V6 | $300 – $800 |

| V8 | $500 – $1500+ |

Please note that these are average ranges and actual prices can vary based on brand, quality, and other factors.

Price Comparisons by Brand and Quality

Similarly, the brand and quality of the crankshaft can have a significant effect on the price. Higher-end brands, known for their quality and durability, generally charge more for their products.

The Cost of Crankshaft Replacement

Labor Costs

In addition to the cost of the crankshaft itself, you’ll also need to factor in labor costs if you’re having the crankshaft replaced. This can vary widely depending on the complexity of the engine and the labor rates in your area, but it can range from $500 to over $1000.

Additional Costs in the Replacement Process

Other costs that might come up during the replacement process include the cost of any additional parts that may need to be replaced (like bearings or seals), as well as any necessary engine work that may be revealed once the engine is opened up for the crankshaft replacement. In some cases, these additional costs can be substantial, so it’s always a good idea to get a comprehensive estimate before proceeding with the replacement.

Also, it’s important to remember that these costs can vary depending on the make and model of your vehicle.

Dealership vs. Independent Mechanic Costs

The cost of crankshaft replacement can also vary depending on whether the work is done at a dealership or an independent mechanic. Dealerships tend to charge more for their services but are usually more familiar with the specific makes and models they service. Independent mechanics may offer lower prices, but their experience with your particular vehicle can vary.

It’s worth getting quotes from both and considering not just the cost, but also the experience, the warranties offered, and the reputation of the service provider.

How to Extend the Lifespan of a Crankshaft

Proper Maintenance Practices

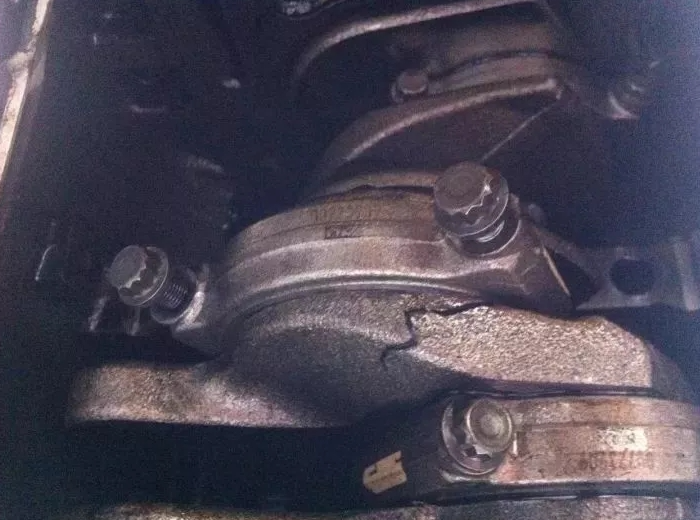

Extending the lifespan of a crankshaft revolves around proper maintenance. Regular oil changes, using quality oil and filters, and avoiding practices that cause excessive engine stress can all contribute to a longer-lasting crankshaft. Periodic inspections of the crankshaft and associated components, such as bearings, can also help identify and resolve issues before they cause crankshaft damage.

Signs of Crankshaft Failure and How to Prevent It

Common signs of impending crankshaft failure include excessive engine vibration, loss of power, oil leaks, or strange noises from the engine. If you notice any of these signs, it’s crucial to get your vehicle inspected as soon as possible to prevent further damage.

定期维护和检查发动机可以帮助防止曲轴故障的许多原因。此外,以不对发动机施加过大压力的方式驾驶也可以延长曲轴的使用寿命。

结论

总之,曲轴的成本可能因发动机类型、材料和生产工艺、品牌和市场条件等因素而有很大差异。虽然前期成本可能很高,尤其是对于高质量曲轴而言,但适当的维护和及时处理任何问题都有助于确保您的曲轴和发动机具有较长的使用寿命。无论您选择在经销商处还是由独立机械师更换曲轴,重要的不仅要考虑成本,还要考虑服务提供商的质量和声誉。

关于曲轴价值的最终想法

评估曲轴的价值

虽然曲轴可能是一项重大投资,但其价值超出了其价格标签。高质量、维护良好的曲轴可以显着延长发动机的使用寿命,提高性能,并防止昂贵的维修费用。从这个角度来看,投资优质曲轴并妥善保养它可以被视为对车辆整体健康和寿命的投资。

[常见问题架构 id=”5927″]