The strongest type of connecting rod is typically made from forged steel or titanium. These materials provide high strength and durability, which is essential for high-performance and commercial applications.

Factors Influencing the Strength of Connecting Rods

Material

Material selection is a crucial factor in the strength of a connecting rod. Common materials include:

Forged Steel Forged steel connecting rods are known for their high strength and durability. They are typically used in high-performance and commercial applications. Learn more about Forged Steel on Wikipedia.

Aluminum Aluminum connecting rods are lighter and can reduce the overall weight of the engine. However, they usually have lower tensile strength compared to steel rods. Visit the Aluminum Wikipedia page for more info.

Titanium Titanium rods offer a good balance between strength and weight, but they are more expensive. Check out the Wikipedia page for Titanium.

Powder Metals Powder metals allow for complex shapes and a potentially lower cost, but may have lower overall strength. Here’s the Powder Metallurgy Wikipedia page.

Manufacturing Process

Different manufacturing processes can also influence the strength of a connecting rod. Let’s explore a few common processes:

Forging Forging results in a denser and stronger final product, making it an excellent process for producing high-strength connecting rods. More on Forging.

Casting Casting is a less expensive process, but it can lead to weaker products due to potential internal defects. You can learn about Casting here.

Machining Machining from billet can lead to higher strength rods as the process allows for precise control over the geometry. Here’s the link to Machining.

Design

The design of a connecting rod can greatly impact its strength. Key design aspects include:

Beam Design The design of the beam of a connecting rod (I-beam or H-beam) can influence its strength and weight. Refer to Mechanical Engineering Design for more information.

Rod Length The length of the rod can affect its strength and the balance of the engine. You can read about Connecting Rods here.

Heat Treatment

Heat treatment can increase the hardness and strength of a connecting rod. The process involves:

Quenching Quenching can increase the hardness of the rod, providing higher wear resistance. Learn more about Quenching on Wikipedia.

Tempering Tempering can reduce the brittleness caused by quenching, making the rod less likely to crack under stress. Here’s the Wikipedia page for Tempering.

Coating

Applying coatings can enhance a connecting rod’s performance and durability. Types of coatings include:

Anti-Friction Coatings These reduce friction between the rod and other engine parts, leading to smoother operation. Visit the Tribology Wikipedia page for more info.

Protective Coatings Protective coatings help to prevent corrosion and wear, enhancing the lifespan of the rod. Check out the Wikipedia page for Coating.

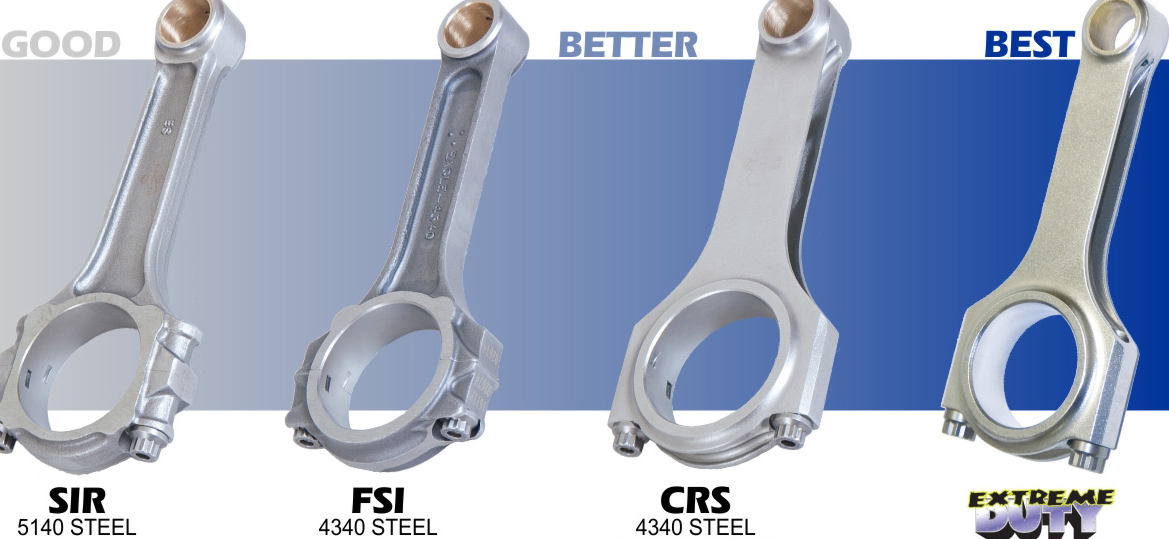

Comparing the Strength of Different Connecting Rod Types

In this section, we’ll compare the strengths of various types of connecting rods using a variety of materials. It’s important to remember that each type has its own advantages and disadvantages, depending on the specific application.

Forged Steel vs. Billet

Both forged steel and billet rods offer great strength, but they are suited for different applications.

Forged Steel rods, due to their manufacturing process, are denser and often stronger. They are great for high-stress applications like in performance or commercial vehicles. You can learn more about Forging here.

Billet rods are made from a solid billet block and then machined into shape. While they are typically stronger than cast rods, they may not be as strong as forged rods. However, their strength can be varied by changing the alloy content. Find more about Machining on Wikipedia.

Billet vs. Aluminum

Comparing billet and aluminum rods involves a trade-off between strength and weight.

Billet rods, as stated before, are known for their strength. They are ideal for applications where strength is the primary concern.

Aluminum rods, on the other hand, are much lighter. This can lead to a more balanced engine and improved RPMs, at the cost of a lower tensile strength. Read more about the properties of Aluminum on Wikipedia.

Aluminum vs. Titanium

The battle between aluminum and titanium rods again comes down to a balance between strength and weight.

Aluminum rods offer the advantage of lightweight performance, as stated before, but can’t match the strength of titanium.

Titanium rods offer a superior strength-to-weight ratio, making them a popular choice for high-performance applications where both strength and weight are considerations. However, this comes at a higher cost. Find more about Titanium on Wikipedia.

Titanium vs. Powder Metal

Both titanium and powder metal rods have unique strengths and weaknesses.

Titanium rods, as discussed, offer an excellent balance of strength and light weight, though at a higher price point.

Powder metal rods offer the ability to form complex shapes and can potentially be lower cost, but they might not have the same strength as a similarly-sized titanium rod. Read more about Powder Metallurgy on Wikipedia.

Applications and Use Cases of Different Connecting Rods

Connecting rods play a pivotal role in many sectors. Their application can differ based on the specific needs of each sector. Let’s discuss how they are used in different fields:

Automotive

Connecting rods in the automotive industry are often subject to harsh conditions, necessitating the use of high-strength materials.

Forged Steel and Billet rods are common in performance and commercial vehicles due to their strength and durability. For more fuel-efficient and lighter vehicles, Aluminum rods may be used. Visit the Automotive Engineering Wikipedia page for more information.

Marine

In the marine sector, connecting rods need to resist the corrosive effects of saltwater and constant exposure to high humidity.

Stainless steel rods are common in marine engines due to their corrosion resistance. On the other hand, Titanium rods may be used in high-performance marine applications for their strength-to-weight ratio. Learn more about Marine Engineering on Wikipedia.

Aerospace

The aerospace industry demands the highest strength-to-weight ratios, as well as exceptional reliability.

Titanium rods are common due to their light weight and strength, despite their higher cost. In some cases, Aluminum or Composite rods may also be used. Visit the Aerospace Engineering Wikipedia page for more info.

Industrial Machinery

Industrial machinery can have a wide range of requirements based on the specific application.

Steel and Iron rods are common in heavy-duty industrial machinery due to their strength. In some cases, Aluminum or Titanium rods might be used to reduce weight. Check out the Industrial Machinery Wikipedia page.

Choosing the Right Connecting Rod for Your Needs

Selecting the right connecting rod depends on a variety of factors, from the type of engine to cost considerations. Let’s explore these in detail:

Considering the Engine Type

The type of engine plays a crucial role in deciding which connecting rod to use.

Internal combustion engines, like those in most cars, usually benefit from the strength of Forged Steel or Billet rods. In high-performance or racing engines, Titanium rods can offer a performance advantage. Visit the Internal Combustion Engine Wikipedia page for more information.

Two-stroke engines, often found in smaller machinery and vehicles, can benefit from the light weight of Aluminum rods. Learn more about Two-stroke Engines here.

The Relationship Between Strength, Weight, and Cost

Understanding the relationship between strength, weight, and cost is critical in choosing the right rod.

Strength is critical in high-stress applications, but stronger materials often come with higher costs.

Weight can impact engine performance, with lighter rods often enabling higher RPMs. However, achieving low weight without sacrificing strength can increase cost.

Finally, Cost is always a consideration, as higher performance materials typically come with higher price tags. Balancing these three factors is key in making the right choice.

Factors Affecting the Choice

Numerous other factors can influence the selection of a connecting rod:

Application: The intended use of the engine can greatly influence the choice of rod. High-performance applications might justify the cost of a titanium rod, for example, while a lower-stress application might best be served by a less expensive material.

Budget: Budgetary constraints can also play a significant role in the choice of a connecting rod. More expensive materials may offer better performance, but may not always be justified by the application.

Availability: The availability of certain types of rods or materials can also affect the choice. Some materials may not be readily available in certain areas or for specific engine types.

For a deep dive into the factors affecting material choice, check the Materials Selection Wikipedia page.

References

- Connecting rod

- Forging

- Aluminium

- Titanium

- Powder Metallurgy

- Machining

- Internal Combustion Engine

- Two-stroke Engine

- Materials Selection

What materials are commonly used to make connecting rods?

How does the manufacturing process influence the strength of a connecting rod?

What factors should I consider when choosing a connecting rod for my engine?

What is the advantage of using aluminum rods?

Why might someone choose a titanium connecting rod?

What is the benefit of heat treating a connecting rod?

How do connecting rods vary between different applications like automotive, marine, aerospace, and industrial machinery?

What is the trade-off between strength, weight, and cost when choosing a connecting rod?