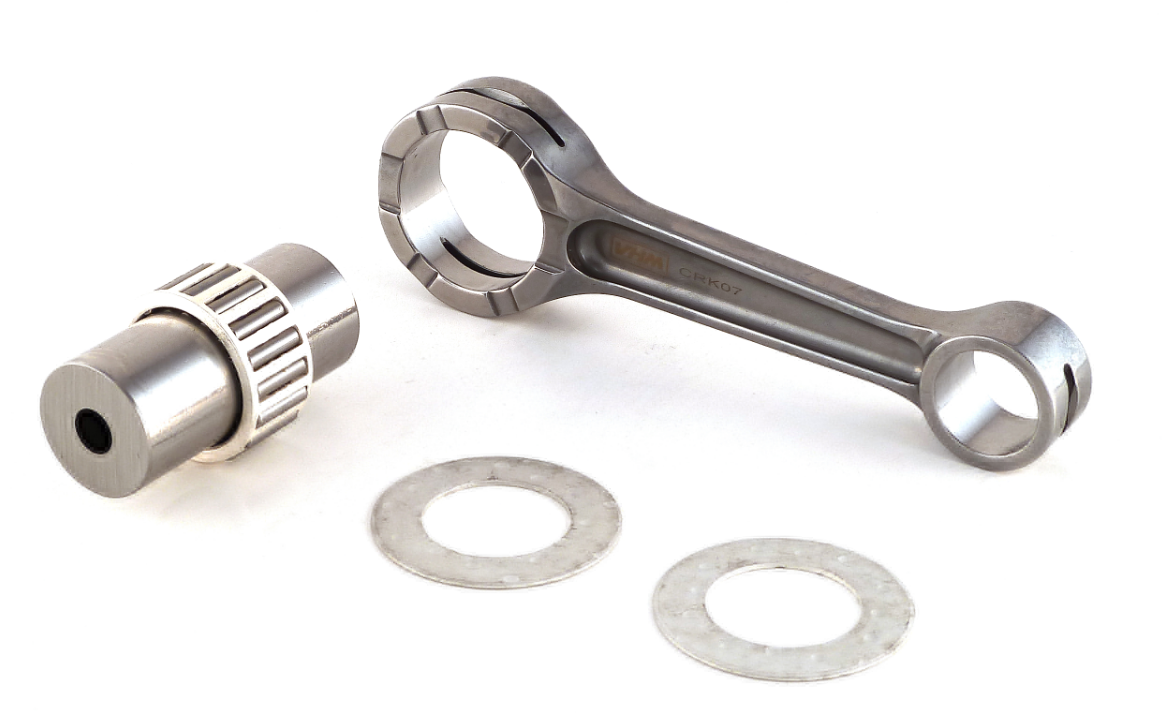

A cast connecting rod, typically made by pouring molten metal into a mold, has inferior strength and durability compared to its counterparts, forged and billet rods. While suitable for many standard applications, cast rods may not hold up under the high-stress conditions of high-performance or racing engines.

Exploring the Properties of a Cast Connecting Rod

Manufactured through a process called casting, these types of connecting rods are made by pouring liquid metal into a predefined mold which, when cooled, forms the final product. The process is relatively quick and cost-effective, making cast rods a common choice for mass-produced, lower performance engines.

Cast rods are relatively brittle compared to forged or billet rods. While they can withstand the normal loads of a stock engine, they tend to fail under the increased stresses of high-performance applications. Moreover, cast connecting rods don’t handle heat as well as their counterparts, potentially leading to deformation or failure under high-temperature conditions.

Forged vs. Cast vs. Billet Connecting Rods

Understanding the difference between cast, forged, and billet connecting rods is crucial to determining the right fit for a given application.

Forged Connecting Rods

Forged connecting rods are made by applying extreme pressure to a piece of metal to change its shape. Forging aligns the grain structure of the metal and improves its overall strength and durability. Forged rods are usually more expensive than cast rods but offer superior performance, making them a popular choice for high-performance and racing engines.

Billet Connecting Rods

Billet connecting rods are made from a single block of metal (often steel or aluminum) that is precisely cut to the required shape. This process creates a highly consistent and strong rod. While billet rods are typically the most expensive of the three types, they provide the highest level of strength and customization.

| Type | Process | Strength | Cost |

|---|---|---|---|

| Cast Rods | Molten metal poured into a mold | Inferior | Lowest |

| Forged Rods | Metal shaped under high pressure | Superior | Moderate |

| Billet Rods | Cut from a single block of metal | Highest | Highest |

Choosing the Right Connecting Rods

The choice of connecting rods largely depends on the specific application and performance requirements. For standard, everyday driving conditions, cast rods might be sufficient due to their cost-effectiveness. However, for high-performance or racing applications where higher strength and heat resistance are crucial, forged or billet rods would be more suitable.

In Conclusion

While a cast connecting rod has the advantage of being more cost-effective, it possesses inferior strength and durability compared to forged and billet rods. Depending on the specific requirements of the engine and the operating conditions it will be subjected to, the right type of connecting rod can significantly influence engine performance and longevity.