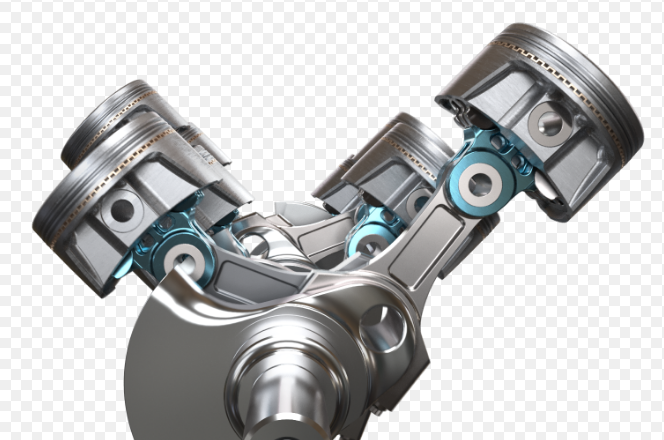

Installing connecting rod bearings in an internal combustion engine is a crucial task that requires precision and careful handling. While the specifics of the process can vary depending on the engine type and the design of the bearing, the overall procedure involves preparing the bearing and the rod, installing the bearing, and then securing it with the connecting rod cap. In this article, we will guide you through the process of installing connecting rod bearings and ensuring their optimal performance.

Understanding the Role of Connecting Rod Bearings

Connecting rod bearings play an integral part in an engine’s operation. They allow the rod to rotate smoothly around the crankshaft, reducing friction and wear. Regular inspection and replacement of these bearings are essential for maintaining the engine’s health and performance.

Preparing for the Installation

Before installing new bearings, it’s crucial to clean the connecting rod and the bearing cap to remove any dirt or debris. It’s also important to inspect the rod and cap for any signs of damage or wear that could impact the fit and performance of the new bearings.

Installing the Connecting Rod Bearings

The installation process involves placing the new bearing into the connecting rod and aligning it carefully. The bearing should fit snugly and evenly in the rod, with the bearing’s notch aligning with the notch in the rod. Once the bearing is in place, it’s crucial to apply a thin layer of engine oil to its surface for lubrication.

Securing the Bearing with the Rod Cap

After installing the bearing into the connecting rod, the next step is to secure it with the rod cap. The cap should align perfectly with the rod, and it’s essential to torque the bolts to the correct specification to ensure a secure fit.

Checking the Installation

Once the connecting rod bearing is installed and secured, it’s essential to check the installation by rotating the crankshaft. The crankshaft should turn smoothly without any resistance or unusual noise, indicating that the bearing is correctly installed and functioning as expected.

Ensuring the Longevity of Your Connecting Rod Bearings

Proper installation of connecting rod bearings is a vital part of engine maintenance. Regular inspection, timely replacement, and correct installation can significantly extend the life of these bearings, ensuring that your engine runs smoothly and efficiently for many miles to come. Remember, the art of how to install connecting rod bearings is a valuable skill that contributes to the longevity and performance of your vehicle.