What Breaks a Crankshaft? Understanding the Causes and Solutions to Crankshaft Failure

The crankshaft, a key component in an internal combustion engine, plays a pivotal role in converting the linear motion of the pistons into rotational motion that ultimately propels the vehicle. But what if this critical component fails? The consequences could be catastrophic, leading to a complete shutdown of the engine, expensive repairs, and potentially, the necessity for a new engine. Understanding the factors that can lead to crankshaft failure, therefore, becomes imperative.

Various elements contribute to the failure of a crankshaft. One of the common causes is overloading. This can occur due to over-revving the engine, where the RPM exceeds the redline limit. Overloading can cause the crankshaft to warp or even break, leading to complete engine failure.

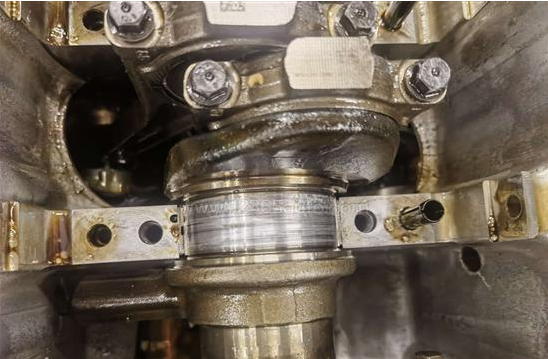

Inadequate lubrication is another factor that can break a crankshaft. Lack of lubrication increases friction between the crankshaft and the bearing surfaces. This excessive friction can result in overheating, wear, and eventual failure of the crankshaft. Regular oil changes and using the correct grade of oil can help to prevent such issues.

Material defects and manufacturing errors can also lead to crankshaft failure. If the metal used to manufacture the crankshaft has imperfections or the manufacturing process is flawed, the crankshaft can fail under normal operating conditions. To prevent this, manufacturers must ensure the quality of the materials used and the accuracy of their manufacturing processes.

Crankshaft failure can also be the result of improper installation. If a crankshaft is not correctly installed, it can be misaligned, leading to uneven wear and eventual failure. The right installation process and regular maintenance checks can help mitigate this risk.

When a crankshaft fails, the engine will typically not function at all. As such, there will be a noticeable loss of power, and in severe cases, the vehicle will not start. Other signs of a failing crankshaft include excessive engine vibration, oil leaks, and unusual noises from the engine.

Fixing a broken crankshaft can be a complex process and typically involves an engine rebuild or replacement. The extent of the damage will determine the exact repair process. It is always advisable to seek professional help when dealing with a broken crankshaft to prevent further damage to the engine.

Regular preventive maintenance can help in reducing the risk of crankshaft failure. This includes timely oil changes, keeping the engine properly tuned, not over-revving the engine, and ensuring the crankshaft is properly installed and aligned. If a crankshaft does fail, it is crucial to understand the underlying cause to prevent recurrence.

In conclusion, knowing what breaks a crankshaft is the first step in preventing crankshaft failure. Whether it’s overloading, inadequate lubrication, material defects, or improper installation, understanding these factors can help in taking the necessary precautions. Although crankshaft failure is a serious issue, with the right knowledge and maintenance, it can be prevented.

Overview: Basic Knowledge About Crankshaft Breakage

The crankshaft is a critical part of an internal combustion engine, which is responsible for converting the reciprocating motion of the pistons into rotary motion, thereby driving the vehicle forward. However, under certain circumstances, the crankshaft may break. This section will provide a general understanding of why this occurs.

Fatigue Failure: The Primary Culprit of Crankshaft Breakage

Most crankshaft failures are due to fatigue failure, which occurs due to the repetitive stress that the component experiences. This can be exacerbated by issues such as poor maintenance and operating beyond the engine’s recommended RPM.

Manufacturing Defects: Hidden Danger to the Crankshaft

Manufacturing defects can also contribute to crankshaft breakage. These defects might include improper materials, incorrect heat treatment, or surface imperfections that weaken the crankshaft.

Overloading: An External Cause of Crankshaft Failure

Overloading the engine, either by over-revving or adding too much power, can cause the crankshaft to fail. It is important to understand the limits of your engine and to operate it within those constraints to avoid crankshaft damage.

Engine Lubrication: A Crucial Factor for Crankshaft Lifespan

Engine lubrication is a key factor in preventing crankshaft failure. Inadequate lubrication leads to increased friction, which can cause the crankshaft to overheat and fail.

Prevention Measures: How to Prevent Crankshaft Breakage

There are several ways to prevent crankshaft breakage, such as regular maintenance, adhering to engine operating guidelines, and ensuring proper lubrication. This section will detail these prevention measures more thoroughly.

Relevant keywords and links: