Contrary to common perception, all connecting rods are not the same. Connecting rods, an integral component of internal combustion engines, come in various forms and materials. These rods differ in their design, composition, and application, thereby serving diverse engine requirements and performance expectations. This article provides a comprehensive understanding of the different types of connecting rods.

Table of Contents

- I-Beam Connecting Rods

- H-Beam Connecting Rods

- A-Beam Connecting Rods

- Material Used in Connecting Rods

- Size of Connecting Rods

- Choosing the Right Connecting Rod

I-Beam Connecting Rods

The I-Beam connecting rods are one of the most common types used in production engines. They are designed with high strength and stability, named after their resemblance to the letter ‘I’ when viewed from the end. I-Beam rods are generally lighter and excellent at absorbing compressive forces, making them suitable for most stock and mildly modified engines.

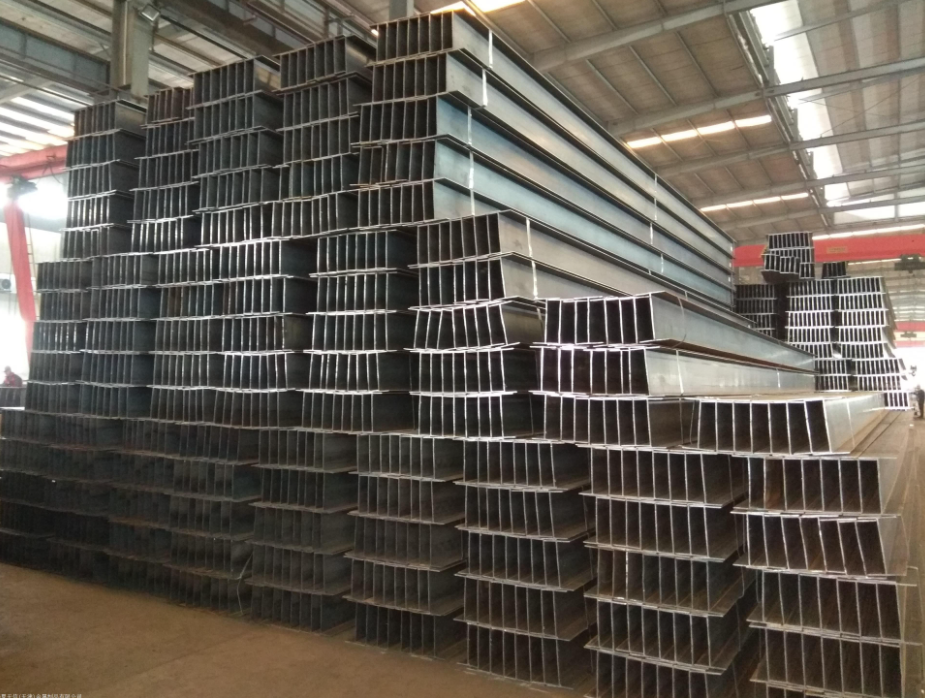

H-Beam Connecting Rods

The H-Beam connecting rods are, as the name suggests, shaped like the letter ‘H’. These rods are often found in high-performance, heavy-duty, and racing applications. They are built to withstand higher RPMs and more forceful piston movements, with their design providing increased rigidity and resistance to bending and twisting forces.

A-Beam Connecting Rods

A-Beam connecting rods, while less common, are designed for specific high-performance applications. The cross-section resembles an ‘A’ shape, giving them a blend of the I-Beam and H-Beam rods’ characteristics. A-Beam rods often provide a good balance between weight and strength.

Material Used in Connecting Rods

Connecting rods can be crafted from various materials, each offering unique characteristics. The most common materials include steel, aluminum, and titanium. Steel rods are known for their durability and strength, while aluminum rods, although less durable, are lighter and allow for higher RPMs. Titanium rods offer the best of both worlds, being both strong and lightweight, but are more expensive.

Size of Connecting Rods

The size of the connecting rod, including its length, width, and thickness, can vary depending on the type of engine. The size directly affects the engine’s compression ratio, RPM capabilities, and overall performance. Therefore, selecting the right size for your specific engine and intended use is critical.

Choosing the Right Connecting Rod

Choosing the right connecting rod depends on your engine’s specifications and your performance needs. Consider factors such as the type of engine, the planned RPM range, the power output, and your budget. If the vehicle is used for daily driving, a standard I-Beam rod is typically sufficient. For more aggressive, high-performance, or racing applications, H-Beam or A-Beam rods may be a better choice.

Through a thorough understanding of the different types of connecting rods, you can make informed decisions about your engine’s components and performance. With this knowledge, you can ensure that your engine is outfitted with the best connecting rod for your specific needs and expectations.