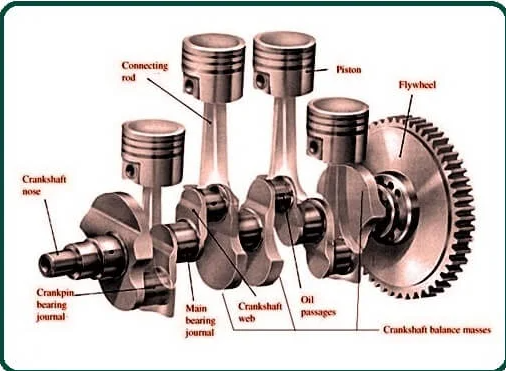

The manufacturing of a crankshaft involves a series of precise and intricate processes to create this vital engine component. It typically includes forging, machining, heat treatment, and surface finishing. These processes ensure the crankshaft’s strength, durability, and precise dimensional accuracy.

Materials Used in Crankshaft Manufacturing

Common Materials for Crankshafts

Steel crankshafts are stronger and more durable than their cast iron counterparts, but they are also more expensive and complicated to manufacture. Some common types of steel used in crankshafts include carbon steel and alloy steel.

In recent years, the use of composites such as carbon fiber in crankshaft production has also gained attention. These materials offer excellent strength-to-weight ratios, but their high cost and manufacturing complexity currently limit their use to high-end or experimental engines.

Considerations for Material Selection

When choosing the material for a crankshaft, several factors come into play:

- Engine performance: High-performance engines require stronger materials to withstand the increased stresses they encounter.

- Cost: More durable and lightweight materials are often more expensive, so cost considerations can limit their use in mass-market vehicles.

- Manufacturing capabilities: Not all materials are equally easy to work with. Factors like the ability to form intricate shapes or the need for special manufacturing equipment can influence material selection.

- Weight: Lighter materials can improve overall engine efficiency and performance, but may also be less durable.

Remember, the material used in the crankshaft’s manufacture will significantly affect its performance and lifespan. Hence, it’s crucial to consider these aspects when designing or selecting a crankshaft for a particular application.

Manufacturing Processes

The creation of a crankshaft involves several intricate processes. Each contributes to the finished product’s strength, durability, and performance. Let’s explore these processes in detail.

Forging

Forging is a common process for the initial shaping of the crankshaft. This method involves heating the metal until it’s malleable and then applying force to shape it. Forging helps align the grain structure of the metal along the shape of the crankshaft, significantly improving its strength and resistance to fatigue.

Machining

Machining processes, such as turning, milling, or grinding, remove excess material from the crankshaft and cut it into its final shape with exacting precision.

Heat Treatment

Heat treatment is an important step in the crankshaft manufacturing process. This process involves heating and cooling the crankshaft in a controlled manner to change the metal’s physical properties. For example, quenching (rapid cooling) can harden the steel, improving its wear resistance, while annealing (slow cooling) can relieve internal stresses and increase toughness.

Surface Finishing

The final process in crankshaft manufacturing is surface finishing. This step ensures the crankshaft’s surface is smooth and free from any imperfections that could lead to premature failure. Surface finishing methods may include polishing to provide a smooth surface and shot peening, which bombards the surface with small particles to improve fatigue resistance.

Each of these steps in the manufacturing process can impact the final crankshaft’s performance and longevity. Understanding these processes can help when selecting a crankshaft, as it gives insight into the quality of its manufacture.

Quality Control in Crankshaft Manufacturing

Quality control is a critical aspect of crankshaft manufacturing. It ensures that the finished product meets or exceeds the necessary specifications and performance standards. Let’s explore some of the methods and standards used to maintain quality control in crankshaft manufacturing.

Inspection and Measurement Techniques

Inspection and measurement techniques play a crucial role in quality control. This might involve visually checking for defects, measuring dimensions with precision tools, or using more complex methods like computer-aided inspection systems. These checks help catch errors early in the process, preventing wastage of resources and ensuring that only defect-free crankshafts proceed to the next stage of production.

Non-Destructive Testing Methods

These techniques allow for the detection of defects without damaging the crankshaft. Common NDT methods in crankshaft manufacturing include magnetic particle inspection (to reveal surface and near-surface defects) and ultrasonic testing (to detect internal flaws).

Certification and Standards

Maintaining high standards and achieving certifications play a significant role in ensuring crankshaft quality. Manufacturers might adhere to various international standards, like ISO (International Organization for Standardization) or ASTM (American Society for Testing and Materials), which define strict requirements for manufacturing processes, testing procedures, and product quality. These certifications offer assurance to consumers about the quality and reliability of the crankshaft.

Through a combination of these inspection, testing, and certification methods, manufacturers strive to ensure that every crankshaft they produce meets high standards of quality, performance, and reliability.

Advanced Manufacturing Techniques

Crankshaft manufacturing has significantly evolved over the years, with technology playing a key role in enhancing precision, efficiency, and flexibility in production.

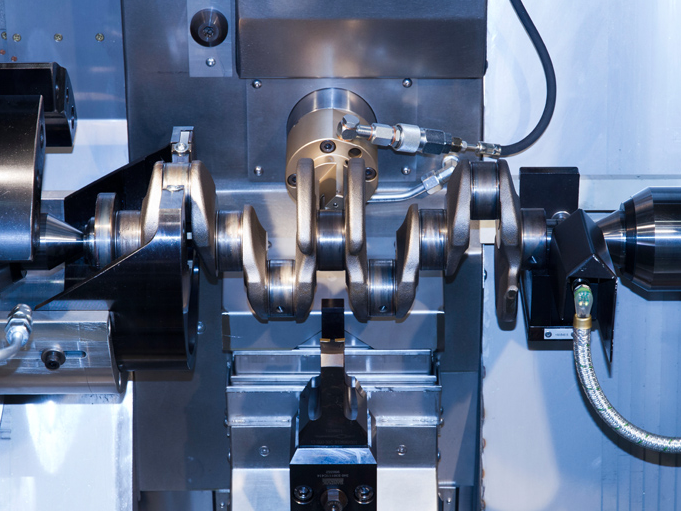

Computer Numerical Control (CNC) Machining

CNC machining has become a standard in modern manufacturing due to its accuracy, consistency, and versatility. In the context of crankshaft production, CNC machines can quickly and precisely carve the intricate shapes necessary for a crankshaft from a solid block of metal. Automated operation reduces human error and increases production speed, allowing for mass production of consistent, high-quality crankshafts.

Computer-Aided Design (CAD) and Simulation

Computer-Aided Design (CAD) is another tool that revolutionizes the manufacturing process. Engineers use CAD software to create precise 3D models of the crankshaft, enabling them to examine and modify the design before manufacturing begins. This ability significantly reduces the time and cost associated with prototype testing.

Additive Manufacturing (3D Printing)

Additive manufacturing, often referred to as 3D printing, is a newer technique that’s starting to find its place in the industry. 3D printing offers exciting possibilities for customization and rapid prototyping. It allows for the creation of complex designs that would be difficult or impossible to achieve with traditional manufacturing methods.

The integration of these advanced manufacturing techniques continues to push the boundaries of what is possible in crankshaft production, delivering higher quality, better performance, and more innovative design solutions.

Specialized Crankshaft Manufacturing

Crankshaft manufacturing often requires special considerations to meet specific demands. Whether it’s for high-performance racing engines, customized applications, or mass-production for original equipment manufacturers (OEMs) and aftermarket suppliers, each sector has unique needs and challenges.

Performance and Racing Crankshafts

They may also feature knife-edged counterweights to reduce windage and aero drag inside the engine. The meticulous design and high-quality materials contribute to the higher price tag of these specialized crankshafts.

Custom and Handcrafted Crankshafts

In custom and handcrafted crankshaft production, the focus is on creating unique parts that meet the exact specifications of a client. Whether it’s for a restoration project, a one-of-a-kind build, or even an unusual machine, custom crankshaft makers use a mix of traditional craftsmanship and modern techniques to achieve the desired result. Although this process is more time-consuming and costly, it provides the flexibility and precision necessary to create perfectly tailored solutions.

OEM and Aftermarket Production

The demand for crankshafts in the OEM and aftermarket sector is high, requiring mass-production techniques. These crankshafts need to meet certain quality standards while being affordable and readily available. Manufacturers often use automated processes such as CNC machining and robotic assembly lines to keep up with the high volume. Although these crankshafts may not have the specialized features of performance or custom models, they provide reliable, cost-effective solutions for everyday driving conditions.

What is the purpose of crankshaft manufacturing?

What materials are used in crankshaft manufacturing?

What is the forging process in crankshaft manufacturing?

What role does machining play in crankshaft manufacturing?

How does heat treatment contribute to crankshaft manufacturing?

What is the significance of surface finishing in crankshaft manufacturing?

How is quality control ensured during crankshaft manufacturing?

Quality control in crankshaft manufacturing involves rigorous inspection, measurement techniques, and non-destructive testing methods to ensure adherence to specifications and standards.