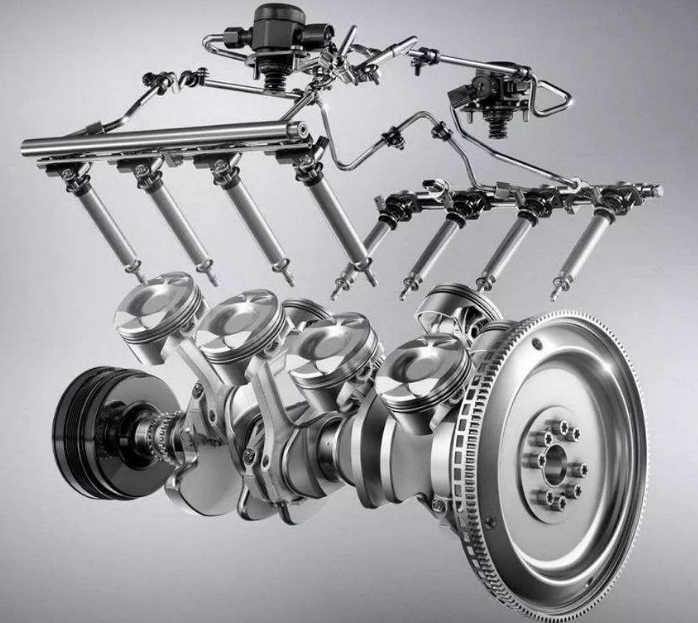

A misaligned connecting rod causes what type of engine wear? Misalignment of connecting rods can lead to various forms of engine wear, adversely affecting the performance, reliability, and longevity of an engine. In this article, we will discuss the consequences of connecting rod misalignment, ways to detect it, and how to prevent it.

Consequences of Connecting Rod Misalignment Misaligned connecting rods can lead to several types of engine wear, including:

- Uneven piston and cylinder wear: A misaligned connecting rod can cause the piston to move unevenly within the cylinder, leading to uneven wear on both the piston and cylinder walls. This wear can reduce compression, power, and fuel efficiency.

- Bearing wear: Misalignment can cause uneven pressure on the crankshaft and piston pin bearings, resulting in excessive wear and potential bearing failure.

- Crankshaft stress: A misaligned connecting rod can put additional stress on the crankshaft, leading to premature wear and potential crankshaft failure.

Detecting Connecting Rod Misalignment There are a few methods to detect misalignment in connecting rods:

- Visual inspection: Inspect the connecting rod for any signs of distortion or damage that may indicate misalignment.

- Measurements: Use precision measuring tools, such as a straightedge and feeler gauge, to check for any discrepancies in alignment between the big end and small end of the connecting rod.

- Engine performance: Monitor engine performance for symptoms of misalignment, such as increased vibrations, decreased power, or excessive oil consumption.

Preventing Connecting Rod Misalignment To prevent connecting rod misalignment and the resulting engine wear, follow these guidelines:

- Proper installation: Ensure that connecting rods are installed according to the manufacturer’s specifications and guidelines, using the correct torque settings and procedures.

- Regular maintenance: Perform regular engine maintenance, including checking connecting rod bolts for proper torque and inspecting the connecting rods for signs of wear or damage.

- Quality components: Use high-quality connecting rods and components that meet or exceed the original equipment manufacturer’s (OEM) specifications.

Conclusion In summary, a misaligned connecting rod causes various types of engine wear, including uneven piston and cylinder wear, bearing wear, and crankshaft stress. By understanding the consequences of connecting rod misalignment, detecting it early, and taking preventative measures, you can help protect your engine from premature wear and prolong its life.