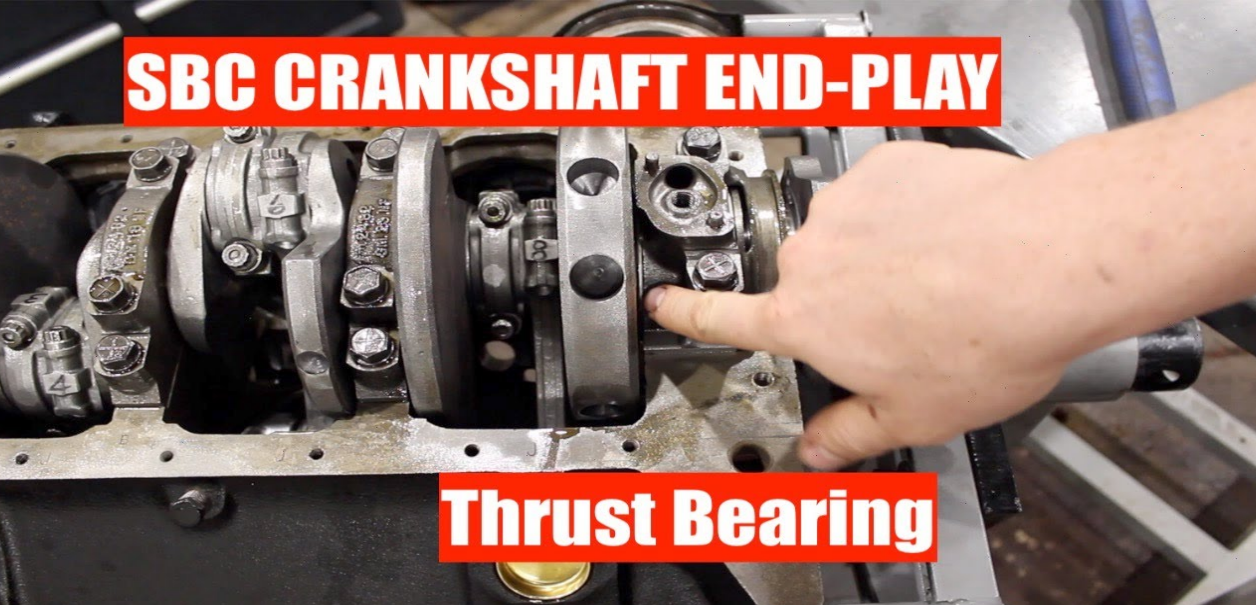

What is a crankshaft? crankshaft is a key component of an internal combustion engine.

It serves the critical role of converting the reciprocating linear motion of the pistons into rotary motion.

This rotary motion then powers the wheels of a vehicle, or other machinery that the engine operates.

In addition to this main function, the crankshaft also transmits power, making it an essential part of an engine’s function and performance.

Introduction

In the world of mechanics and engineering, the crankshaft is a fundamental component. Its main role is to convert the linear motion of the pistons into a rotational motion that drives the vehicle’s wheels or other machinery.

Definition of a Crankshaft

A crankshaft is a moving part of an internal combustion engine or a similar machine. It changes reciprocating linear piston motion into rotation.

This underlines the importance of regular inspection and maintenance.

The design and materials of a crankshaft vary based on the engine type and the demands of the particular application. However, regardless of these differences, the fundamental purpose remains the same – to convert linear motion into rotation.

History of Crankshafts

The crankshaft, while an integral part of modern machinery, has a history dating back thousands of years. Its initial concept and early use vastly differ from today’s advanced and precision-engineered designs. Over time, its design and manufacturing processes have evolved, allowing it to become more efficient and capable of withstanding greater forces.

Origin and Early Use

The concept of the crankshaft has its roots in antiquity.

In the context of engines, the earliest known use of a crankshaft in a pump was by the ancient Chinese during the Han Dynasty. It allowed for a more efficient conversion of motion compared to previous designs.

Developments Over Time

The industrial revolution led to significant advancements in the design and use of crankshafts. With the advent of the steam engine, the design of the crankshaft evolved to handle more considerable forces and higher rotational speeds.

The introduction of the internal combustion engine brought further changes.

Computer-aided design (CAD) and computer-aided manufacturing (CAM) processes have made it possible to produce crankshafts with a high degree of precision and consistency.

Design and Construction of Crankshafts

Crankshafts are vital components in an engine, and their design and manufacturing processes are of the utmost importance. They require a specific selection of materials, advanced manufacturing methods, and a host of considerations to ensure they meet the rigorous demands of modern engines.

Materials

The choice of material depends on the engine type and its intended use. High-performance engines usually employ forged steel crankshafts due to their superior strength and durability. Cast iron, while not as strong as steel, is less expensive and has excellent damping capacity, making it a popular choice for many consumer vehicles.

Manufacturing Processes

The manufacturing process of a crankshaft is multifaceted, involving several stages. The first is forging or casting the basic shape of the crankshaft. Forging offers more strength but is a more expensive process, while casting is more affordable.

Once formed, the crankshaft undergoes heat treatment to improve its hardness, followed by machining to finalize its shape. This includes the formation of critical surfaces such as main journals and crankpins.

This involves adding or removing material to ensure the crankshaft can rotate smoothly without inducing excessive vibrations.

Design Considerations

Designing a crankshaft involves a variety of factors. Firstly, the crankshaft must be strong enough to withstand the forces exerted by the pistons. It also needs to be lightweight to reduce rotational inertia and enhance engine responsiveness.

The number and arrangement of the crankpins, relative to the main journals, dictate the engine’s firing order and balance.

Through careful selection of materials, precise manufacturing, and meticulous design considerations, crankshafts can deliver reliable and efficient performance in a wide range of engine applications.

Functions of a Crankshaft

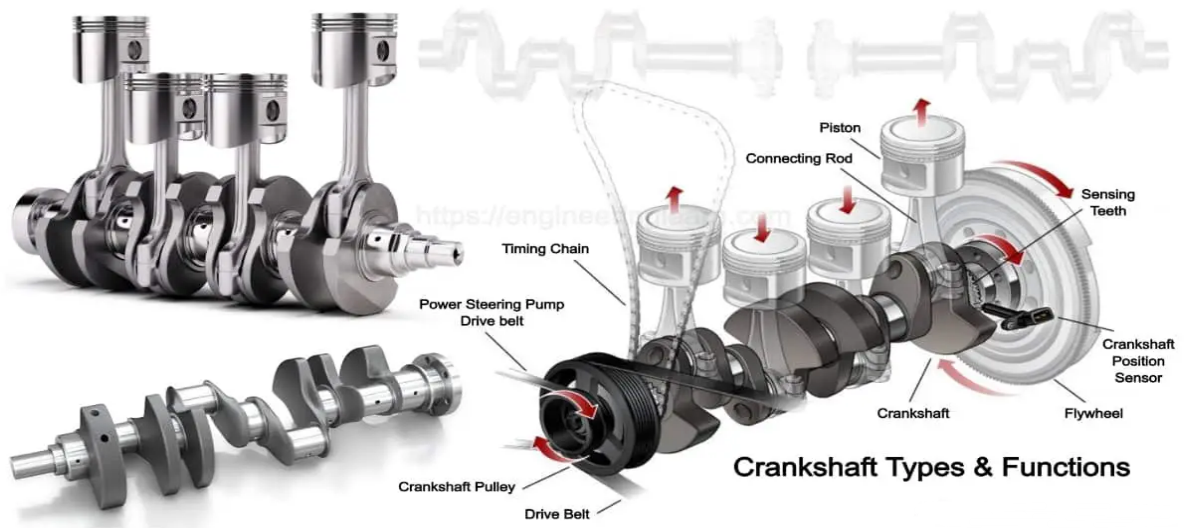

A crankshaft is a core component of an internal combustion engine, serving two primary functions: the conversion of linear motion to rotary motion and the transmission of power.

Conversion of Linear Motion to Rotary Motion

The primary function of a crankshaft is to convert the linear motion of the pistons into rotary motion.

As the pistons move up and down during the engine cycle, they push on the crankpins, causing the crankshaft to rotate. This transformation of motion is based on basic principles of mechanics and is vital for the engine’s operation.

Transmission of Power

The secondary but equally important function of the crankshaft is the transmission of power.

The crankshaft connects to other components of the drivetrain, such as the transmission, via a flywheel or a flexplate.

In summary, the crankshaft serves as the link between the engine’s combustion process and its mechanical output, converting the reciprocating motion of the pistons into a usable rotational force that can drive machinery or propel a vehicle.

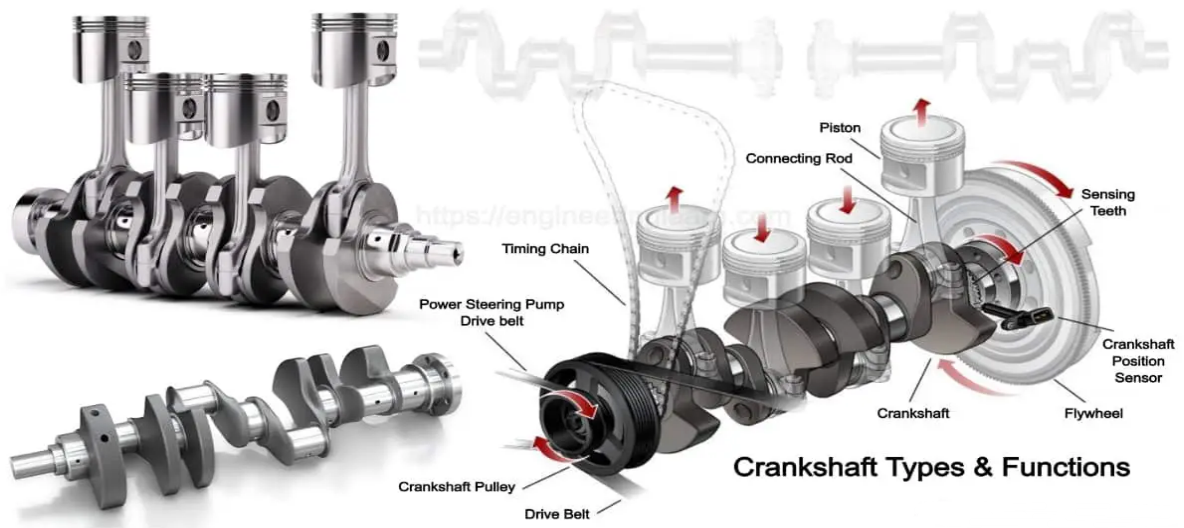

Types of Crankshafts

Crankshafts come in different types, primarily distinguished by their construction method. The two most common types are monolithic crankshafts and built-up (assembled) crankshafts. Each type has its unique advantages and considerations.

Monolithic Crankshafts

A monolithic crankshaft, also known as a one-piece crankshaft, is made from a single piece of material.

Monolithic crankshafts are incredibly robust and durable due to their unibody design.

However, manufacturing a monolithic crankshaft is a complex process requiring precision and high-quality materials, making it more expensive than other types.

Built-up (Assembled) Crankshafts

In contrast to monolithic crankshafts, built-up crankshafts, sometimes referred to as assembled crankshafts, are made of multiple parts. These parts, such as the crankpins and main journals, are constructed separately and then assembled to form the crankshaft.

However, built-up crankshafts may not withstand high loads as effectively as monolithic crankshafts due to the assembly points potentially serving as weak spots.

In conclusion, the choice between a monolithic and built-up crankshaft depends on the specific application, considering factors like cost, performance requirements, and maintenance needs.

Key Components and Terms Related

Familiarity with these components and related terms can assist in understanding the crankshaft’s function and importance.

Crankpins

Crankpins, also known as rod journals, are the areas of the crankshaft where the connecting rods attach. They move up and down as the crankshaft rotates, transforming the pistons’ linear motion into rotation.

Main Journals

Main journals are the areas of the crankshaft that rest on the engine block’s bearings and upon which the crankshaft rotates. Their size and placement are crucial to the crankshaft’s balance and the engine’s overall smoothness of operation.

Counterweights

They are crucial to minimizing engine vibration. The positioning and design of counterweights need careful consideration to ensure they provide balance without adding unnecessary weight to the crankshaft.

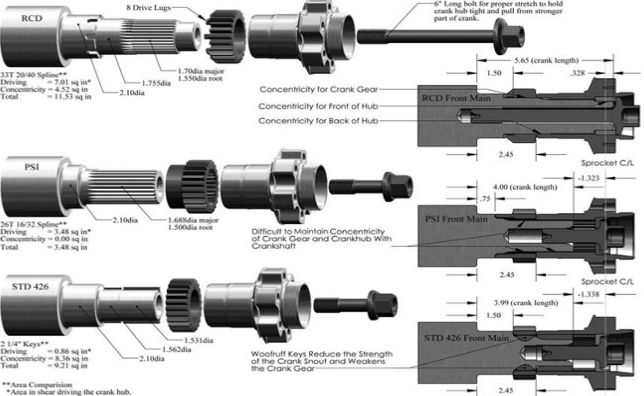

End-play

Crankshaft end-play, also known as thrust play, is the allowable lateral movement of the crankshaft within the engine block.Excessive end-play can lead to damage and premature wear on the engine.

Understanding these components and terms helps to highlight the complexity of crankshaft design and the importance of each part in ensuring the proper function of the engine.

Crankshaft in Different Engines

While the basic function of a crankshaft – to convert linear motion into rotary motion – remains the same, the design, materials, and specific application can vary widely depending on the type of engine.

Crankshaft in Petrol Engines

In petrol engines, also known as gasoline engines, the crankshaft has to withstand high rotational speeds. These engines typically operate at higher RPMs compared to diesel engines, which puts significant stress on the crankshaft. They also require precise balancing to ensure smooth operation at high speeds.

Crankshaft in Diesel Engines

Diesel engines operate at lower RPMs compared to petrol engines but produce higher torque. Diesel engine crankshafts also have larger main journals and crankpins to distribute the increased load.

Crankshaft in Two-Stroke and Four-Stroke Engines

The design of crankshafts also varies between two-stroke and four-stroke engines. In a two-stroke engine, the crankshaft makes one revolution for each power stroke, leading to higher rotational speeds. Two-stroke engines often use built-up crankshafts, which can contain passages for the fuel-air mixture.

On the other hand, a four-stroke engine makes two crankshaft revolutions for each power stroke. Four-stroke engines generally use monolithic crankshafts due to their strength and durability. The lower rotational speed relative to two-stroke engines allows for a heavier, more robust crankshaft design.

Common Problems and Maintenance of Crankshafts

Like all mechanical components, crankshafts are susceptible to wear and tear over time and require regular maintenance to ensure longevity. Understanding common issues, repair options, and preventative measures are essential in maintaining the performance and reliability of an engine’s crankshaft.

Wear and Tear

Crankshaft wear and tear typically occurs on the surfaces of the crankpins and main journals due to friction. Regularly high RPMs, insufficient lubrication, or contamination in the oil can accelerate this wear. Over time, this can lead to decreased engine performance and, in severe cases, engine failure.

Brands like FEDA recommend regular engine checks to catch these problems early before they lead to more serious damage.

Repair and Maintenance

Regular maintenance of a crankshaft primarily involves ensuring proper lubrication. Regular oil changes using high-quality engine oil are essential. FEDA also recommends regular engine inspections to ensure that the oil delivery system is functioning correctly and that the crankshaft is in good condition.

Preventative Measures

Preventative measures can significantly extend the lifespan of a crankshaft and improve engine performance. These measures include regularly checking and maintaining engine oil levels and quality, avoiding unnecessary high RPM operation, and having regular engine inspections to detect issues early.

Using components from reputable manufacturers like FEDA can also be a good preventative measure. High-quality components are more resistant to wear and tear, and the manufacturers often provide comprehensive guidance on proper maintenance practices.

In conclusion, although crankshafts are robust components, they require regular maintenance and attention to ensure they remain in optimal working condition and prolong their service life.

References:

- Crankshaft – Wikipedia

- Two-stroke engine – Wikipedia

- Four-stroke engine – Wikipedia

- Diesel engine – Wikipedia

- Petrol engine – Wikipedia