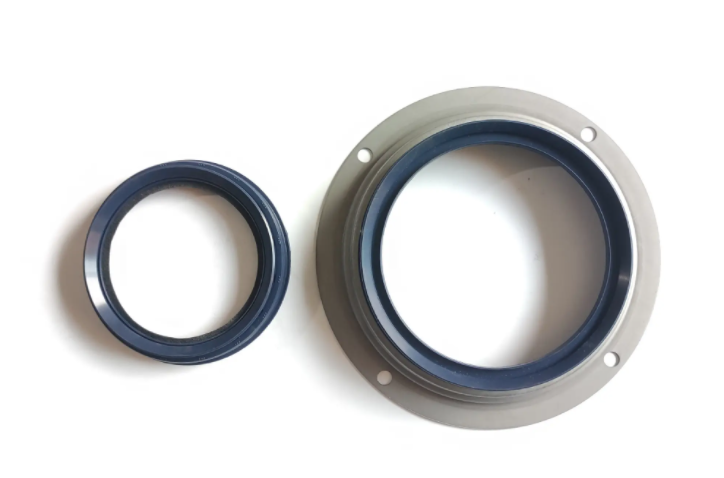

Crankshaft seals are essential components in engines, ensuring the proper containment of oil and preventing leaks. These seals help maintain peak performance in engines and protect the vital parts from excessive wear and tear. In this article, we’ll delve into the world of crankshaft seals and discuss their importance in engine operation.

Engine performance and longevity rely heavily on the effectiveness of crankshaft seals. These small components seal the gaps between the engine block, oil pan, and crankshaft, preventing oil from escaping and dirt from entering. For a unique perspective on crankshafts, check out crankshaft road bike, where you’ll learn about the adaptation of crankshaft technology for bicycles.

When it comes to maintaining a healthy engine, the quality of the crankshaft seals is crucial. High-quality seals are less likely to fail or wear out prematurely, ensuring your engine continues to operate smoothly. It’s essential to choose seals made from durable materials, such as rubber or silicone, that can withstand the high temperatures and pressures experienced within an engine.

For more in-depth information about crankshafts and their function within gasoline engines, visit What is a Crankshaft: Exploring the Functions, Advantages, and User Experiences in Gasoline Engines.

Connecting rods are another crucial engine component, transferring power from the pistons to the crankshaft. If you’re interested in learning more about specific connecting rods, such as those designed for Chevy 350 engines, explore chevy 350 connecting rods.

In conclusion, crankshaft seals play an indispensable role in maintaining engine performance and prolonging the life of your vehicle’s engine. By investing in high-quality seals and keeping an eye out for potential issues, you can ensure your engine operates at peak efficiency and prevent costly repairs down the line.