The main engine crankshaft is a crucial component of an internal combustion engine that converts the reciprocating linear motion of the pistons into rotational motion.

This conversion of motion allows the driving of the vehicle’s wheels and the operation of other engine components.

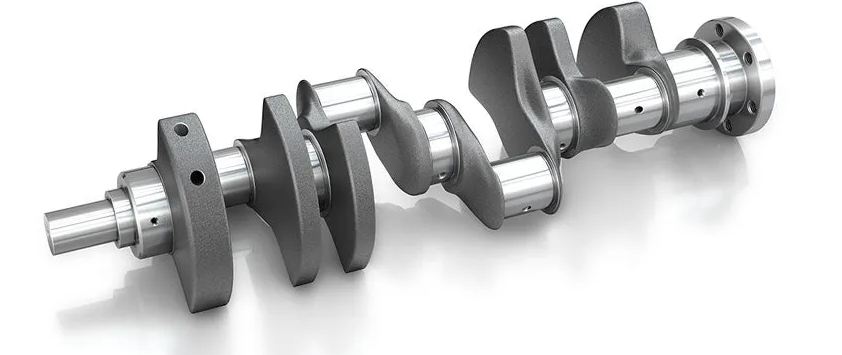

Introduction to the Main Engine Crankshaft

The main engine crankshaft is a critical component in an engine that converts linear motion into rotational motion. This crucial process forms the basis of modern vehicular engines and is integral to their operation.

Brief Overview

The crankshaft is a moving part of the internal combustion engine (ICE). It experiences torque (force) from the piston and connecting rod, converting it into a rotation that drives the vehicle’s wheels or other equipment.

Significance in Engine Operation

The crankshaft’s primary role is to transform the linear (back-and-forth) motion of the pistons into rotational motion.As such, the crankshaft is not only a vital component of an engine but fundamentally, it’s the backbone of any vehicular propulsion system. Furthermore, the crankshaft also acts as a mechanical arm, facilitating the movement of pistons within the cylinders, thus playing a vital role in the internal combustion engine’s four-stroke cycle: intake, compression, power, and exhaust.

Components of a Crankshaft

The crankshaft is more than just a single piece of metal.

Main Journals

The size and number of main journals can vary depending on the design of the engine, but their primary function is to provide a stable and robust support system for the crankshaft during its rotation.

Connecting Rod Journals (or Crankpins)

Connecting rod journals, also known as crankpins, are areas on the crankshaft where the connecting rods attach. These journals rotate within the big-end bearings of the connecting rods, transmitting the force from the pistons to the crankshaft, and ultimately converting linear motion into rotational motion.

Counterweights

By equalizing these forces, counterweights help to minimize vibration and improve engine performance.

Thrust Bearings Surfaces

The thrust bearing surfaces on a crankshaft work to manage the axial or longitudinal loads exerted on the crankshaft. These loads occur due to the reaction forces from the pistons during the combustion process. Thrust bearings are crucial in limiting the longitudinal movement of the crankshaft within the engine block, keeping it aligned along its rotational axis.

Crankshaft Flange

The crankshaft flange is the end portion of the crankshaft, typically where it connects to the transmission or other drivetrain components. It often has holes or studs for attaching a flywheel or similar device. The flange needs to be robust and accurately machined as it has to withstand the rotational forces of the crankshaft while accurately transferring the rotational motion to the rest of the drivetrain.

Functionality of the Crankshaft

The crankshaft, despite its simple appearance, performs critical tasks in an engine’s operation. The primary roles of the crankshaft include converting linear motion into rotational motion and distributing power to other engine components.

Converting Linear Motion into Rotational Motion

The fundamental function of a crankshaft in an internal combustion engine is to convert the linear motion of the pistons into rotational motion. This conversion process is crucial because most mechanical devices, such as vehicles and generators, need rotational motion to operate.

During the power stroke of the engine, the combustion of the air-fuel mixture in the cylinder exerts force on the piston, driving it downward.The crankshaft, with its uniquely curved structure, transforms this linear motion into a rotational motion that eventually spins the wheels of a vehicle or drives other equipment.

Delivering Power to Other Components

Besides its primary role of motion conversion, the crankshaft also functions as a ‘power distributor’ within the engine. As the crankshaft rotates, it drives other engine components, including the oil pump, water pump, and alternator via various belts connected to the crankshaft pulley.

In this way, the crankshaft doesn’t only facilitate the vehicle’s movement but also ensures that other vital subsystems like cooling (water pump), electrical charging (alternator), and engine lubrication (oil pump) are functioning properly. This critical aspect of delivering power underscores the importance of the crankshaft’s operational integrity in the overall performance and health of the engine.

Materials and Manufacturing of Crankshafts

The production of a crankshaft involves careful material selection, specialized manufacturing processes, and rigorous testing to ensure that the finished product can withstand the extreme pressures of an engine’s operation.

Commonly Used Materials

Various materials are used in the production of crankshafts, each selected for its unique properties that make it suitable for the application.

- Forged Steel: Forged steel crankshafts are often found in high-performance and commercial vehicles. The forging process results in a stronger, more durable crankshaft that can withstand higher pressures and loads.

- Alloy Steel: In high-performance engines where weight and strength are crucial, alloy steels such as chromium and nickel-chromium steels are used. These materials offer high strength-to-weight ratios and excellent fatigue resistance.

Manufacturing Processes

The manufacturing of a crankshaft generally involves a series of processes:Heat Treatment: The formed crankshaft undergoes heat treatment to improve its hardness and durability.

Quality Control and Testing

Quality control and testing are essential aspects of crankshaft production. To ensure the crankshaft can handle the stresses of engine operation, it undergoes several tests, including dimensional checks, hardness tests, and crack detection inspections.

This process involves adding or removing material from the counterweights to minimize vibration during operation. Without this balancing process, the engine would experience significant vibration and shortened life due to the uneven distribution of forces.

Types of Crankshafts

There are several types of crankshafts, and their usage depends on various factors like engine size, power output requirements, cost considerations, and more. Here, we discuss two main types of crankshafts: monolithic and assembled.

Monolithic Crankshafts

The manufacturing process of a monolithic crankshaft involves shaping the entire crankshaft — including its main and rod journals, flanges, and counterweights — from a single piece of metal. This one-piece design offers excellent structural integrity, making the monolithic crankshaft less likely to fail under high stress.

Assembled Crankshafts

One key advantage of the assembled crankshaft is the possibility to use different materials for different parts, allowing manufacturers to optimize for weight, strength, and cost. However, the assembly process can be complex and requires high precision to ensure the assembled crankshaft operates reliably.

Comparison and Use Cases

Both monolithic and assembled crankshafts have their advantages and applications.They can withstand high pressures and loads, making them suitable for high-stress environments.

They allow for performance optimization but require a high degree of precision in their assembly.

Ultimately, the choice between a monolithic and an assembled crankshaft depends on the specific requirements of the engine, including its size, power output, and intended use.

Problems and Failures in Crankshafts

Identifying these issues early on and taking appropriate measures can prevent further damage and costly repairs.

Common Issues

Common issues with crankshafts can result from a variety of causes, including:

- Cracks and Breakage: These can result from metal fatigue, improper material selection, or manufacturing defects. Cracks can eventually lead to the catastrophic failure of the crankshaft.

- Wear: Over time, the constant friction between the crankshaft and its bearings can lead to wear, especially on the journals.

- Bearing Failure: The bearings that support the crankshaft can fail due to inadequate lubrication, contamination, or overloading. This can result in damage to the crankshaft itself.

Symptoms of Crankshaft Problems

Recognizing the symptoms of a crankshaft problem can help diagnose and address issues before they become serious. Symptoms may include:

- Excessive Vibration: Unusual or excessive vibration could be a sign of an out-of-balance crankshaft.

- Engine Knocking Noise: A distinctive knocking noise from the engine could indicate worn or damaged crankshaft bearings.

- Oil Leaks: Leaking oil might be a symptom of a damaged crankshaft seal.

- Engine Performance Issues: Issues such as power loss, poor fuel efficiency, or difficulties in starting the engine could point to a problem with the crankshaft.

Damage Control and Repairs

This usually involves consulting a professional mechanic or technician.

Minor issues such as slight wear or minor imbalance can often be rectified with machining or balancing procedures. However, more severe problems like deep cracks, severe wear, or major balance issues might necessitate a crankshaft replacement. It is also crucial to address any underlying issues that may have led to the crankshaft damage, such as bearing failures, oil leaks, or vibration issues.

Regular maintenance, including oil changes and inspections, can also help prevent many common crankshaft problems.