Automotive Connecting Rods Manufacturers” represent an elite cadre of industry leaders worldwide. These manufacturers, with their unparalleled technology, innovative drive, and stringent quality control, make crucial contributions to the automotive industry, crafting the heart of the engine, the connecting rods, with meticulous precision

Overview of Automotive Connecting Rods

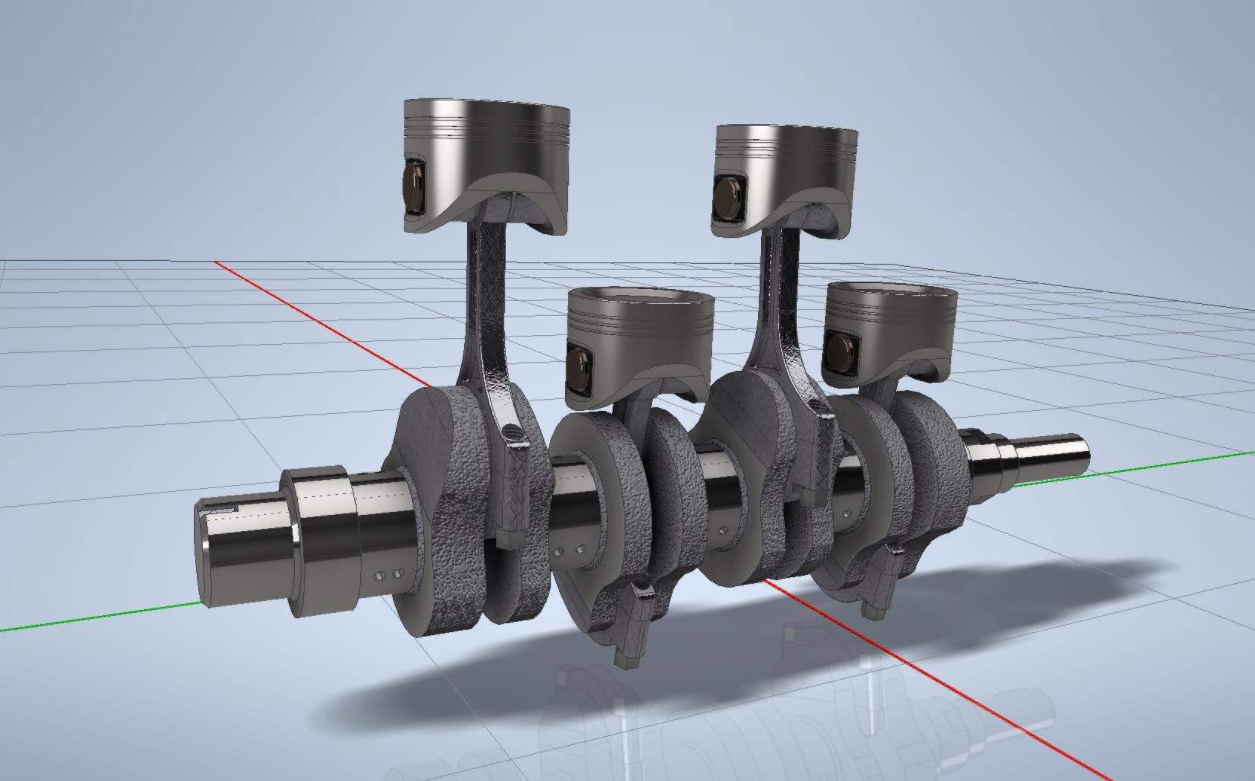

Automotive connecting rods, an integral component of any combustion engine, are designed to transfer motion from the piston to the crankshaft, thereby converting reciprocating motion into rotating motion. Connecting rods, often made from steel or aluminum alloys, are subjected to strenuous forces and must maintain their strength and durability while being as light as possible.

There are a variety of types, including I-Beam, H-Beam, and A-Beam rods, each with unique characteristics tailored to specific engine requirements. For further understanding of these types, you may refer to the Connecting Rod article on Wikipedia.

Importance of Connecting Rods

Connecting rods play a vital role in determining an engine’s performance and longevity. High-quality rods improve efficiency and reduce wear and tear, making them a crucial consideration for automotive manufacturers.

Materials and Manufacturing Techniques

Traditionally, steel and aluminum alloys have been the go-to materials for manufacturing connecting rods. However, recent trends show a shift towards more advanced materials like titanium and composites for their superior strength-to-weight ratio. To know more about these advancements, refer to this Automotive Industry article on Wikipedia.

The primary audience for this article includes automotive industry professionals, engine builders, and car enthusiasts. The information may also be valuable to students and researchers in the field of automotive engineering. The article also refers to this Automotive Engineering article on Wikipedia for more insights.

An Overview of Leading Automotive Connecting Rods Manufacturers

This section presents an overview of the leading manufacturers in the automotive connecting rods industry. These companies have been selected based on their global presence, market share, historical background, and the innovative products they offer.

Global Presence and Market Share

Automotive connecting rods manufacturers span across various continents, each having a significant market share in their respective regions and globally. The table below shows some of the leading manufacturers, their location, and estimated global market share:

Please note that market shares are dynamic and subject to change due to a multitude of factors such as economic conditions, technological advancements, and consumer preferences. More detailed information can be found on the Automotive Industry page on Wikipedia.

An Overview of Leading Automotive Connecting Rods Manufacturers

In the automotive industry, there are several leading manufacturers known for their outstanding products and global market presence. This section takes a closer look at some of these companies, including FEDA, a renowned company specializing in engine parts.

Global Presence and Market Share

The global landscape of automotive connecting rod manufacturers is diverse and competitive. Here are some notable companies in the industry:

- FEDA: An internationally acclaimed manufacturer and exporter of auto engine parts.

Brief History and Background of Each Manufacturer

Understanding the history and background of these manufacturers can provide insightful context about their product offerings and market position.

- FEDA: Sichuan Feda International Trade Co., Ltd. has been specializing in the production and export of auto engine parts, mainly connecting rods and crankshafts, for over 20 years. These parts cater to a wide array of automobile engines from leading car manufacturers like Benz, Volvo, BMW, Porsche, VW, Audi, Peugeot, Ford, Chevrolet, Toyota, Nissan, Mitsubishi, Hyundai, and more. FEDA products are internationally recognized and have been extensively sold in America, Europe, and other countries. The company’s emphasis on professional technology, precision tools, and customized production has earned them a prestigious position in the industry.

Detailed Review of Products by Each Manufacturer

Each of these manufacturers has a distinct line of products that cater to different market needs. This section delves into the specifics of their offerings:

FEDA

FEDA offers a broad range of connecting rods and crankshafts suitable for various automobile engines. These products are renowned for their superior quality, designed and manufactured with the highest precision. Their range caters to multiple high-profile car manufacturers, and they are also capable of designing and producing parts as per customer’s special requirements.

For a more detailed review of each product, please visit the respective manufacturer’s website or the Wikipedia page on Automotive Components.

Range of Connecting Rods

Automotive connecting rod manufacturers typically offer a wide range of products to cater to various engine types and performance requirements. These include standard rods for typical passenger cars, high-performance rods for racing cars, and heavy-duty rods for commercial vehicles. Among these manufacturers, FEDA stands out for its extensive selection, catering to a vast array of automobile engines.

Heavy-Duty Connecting Rods

These rods are typically larger and heavier, made of high-strength alloys to withstand extreme pressures.

Unique Features and Specifications

Each manufacturer offers unique features and specifications to differentiate their products in the market. For instance, FEDA connecting rods are known for their precision design, superior materials, and high-quality manufacturing process.

Materials and Construction

Different materials, including steel, aluminum, titanium, and composite materials, are used in the construction of connecting rods. The choice of material impacts the rod’s strength, weight, and heat resistance.

Design Specifications

The design of connecting rods can greatly impact engine performance. Aspects such as rod length, weight, and shape can alter an engine’s horsepower, torque, and efficiency.

Additional Features

Manufacturers often include additional features to enhance the performance or durability of their connecting rods. This can include things like advanced bearing designs, special coatings to reduce friction, or reinforced designs for added strength.

Comparative Analysis of Products

Comparing products from different manufacturers can help potential buyers choose the best connecting rod for their specific needs. Here, we will briefly compare the products from our discussed manufacturers, including FEDA.

When making a comparison, some key aspects to consider include the range of products offered, the unique features and specifications of the rods, and the target applications (i.e., standard, high-performance, or heavy-duty applications). For instance, FEDA, with its wide product range and commitment to quality, stands out in the industry.

For more detailed comparisons and information about the performance and specifications of various connecting rods, consider visiting the respective manufacturers’ websites or refer to resources like the Automotive Components page on Wikipedia.

Advanced Materials Used

In the production of automotive connecting rods, manufacturers are constantly exploring and adopting advanced materials to improve product performance and durability. Some of these materials include:

| Material | Advantages | Common Usage |

|---|---|---|

| Steel | High strength, good fatigue resistance, cost-effective | Standard and heavy-duty applications |

| Aluminum | Lightweight, good heat resistance | High-performance and racing applications |

| Titanium | Exceptional strength-to-weight ratio, corrosion resistance | High-performance and racing applications |

| Carbon Fiber Composites | High strength-to-weight ratio, excellent fatigue resistance | High-performance and racing applications |

To learn more about the material properties and their impact on automotive parts, you can visit the Automotive Engineering page on Wikipedia.

Manufacturing Techniques and Technologies

Over time, automotive connecting rod manufacturers have evolved their manufacturing techniques and technologies to enhance production efficiency and product quality. Here are a few prevalent techniques:

Forging

Forging is a common technique used in the manufacture of connecting rods. It involves heating a piece of metal and then using a die to shape it into the desired form. This technique enhances the strength and durability of the connecting rod.

Casting

Casting involves pouring molten metal into a mold of the desired shape and allowing it to cool and harden. This technique is often used for manufacturing large quantities of connecting rods efficiently.

Machining

Machining involves using tools to shape a piece of metal into the desired form. With the advent of computer numerical control (CNC) machines, this process can be highly automated and precise, producing connecting rods with extremely tight tolerances.

Research and Development Efforts

Continuous research and development are crucial in the automotive industry to stay ahead of the curve. Manufacturers like FEDA invest heavily in their R&D efforts to explore new materials, optimize design, improve manufacturing processes, and test the performance and durability of their products.

Through these efforts, manufacturers aim to improve the performance of their products, reduce costs, enhance production efficiency, and reduce their environmental impact.

Quality Control Procedures

To ensure the production of high-quality connecting rods, manufacturers like FEDA implement stringent quality control procedures throughout their manufacturing process. This includes regular inspections at each stage of production, from raw material sourcing to the final assembly. High-tech equipment and advanced techniques are employed to measure the accuracy and quality of the products.

Process Inspection

During the manufacturing process, the connecting rods are inspected at different stages. This includes checking the dimensions, weight, and other specifications of the rods after each major production step.

Final Inspection

Before the connecting rods are shipped out, they undergo a final round of inspection. This includes visual inspections for any defects and functional tests to ensure they perform as expected.

Certifications and Standards Compliance

To reassure customers about the quality of their products, manufacturers often obtain various certifications and ensure their products comply with international standards. For instance, FEDA ensures that all their products meet or exceed industry standards and have obtained necessary certifications.

Manufacturers must comply with various standards, including ISO 9001 for quality management systems and ISO/TS 16949 for automotive quality management. Compliance with these standards demonstrates a manufacturer’s commitment to quality and customer satisfaction.

Customer Reviews and Feedback

Customer reviews and feedback are a valuable resource for prospective buyers and play a crucial role in improving the products and services provided by the manufacturer. FEDA, like many manufacturers, values customer feedback and uses it to continually improve their products and services.

Positive reviews can attest to the quality of a manufacturer’s products, their customer service, and their reliability. At the same time, constructive feedback can help manufacturers identify any issues or areas for improvement. To understand more about the reputation and credibility of manufacturers, one can refer to their official websites, customer review platforms, or industry forums.

To learn more about quality management in the automotive industry, you can visit the ISO/TS 16949 page on Wikipedia.

Eco-friendly Manufacturing Practices

In response to increasing environmental concerns, many automotive connecting rod manufacturers have adopted eco-friendly manufacturing practices. These practices aim to minimize waste, reduce energy consumption, and limit the environmental impact of the manufacturing process.

Energy-Efficient Manufacturing

By adopting energy-efficient technologies and practices, manufacturers can significantly reduce their energy consumption. This includes optimizing production processes, using energy-efficient equipment, and implementing energy management systems.

Emissions Control

Manufacturers also strive to control and reduce emissions from their production facilities. This involves using cleaner fuels, implementing emissions control systems, and regularly monitoring and managing emissions.

Sustainable Materials and Designs

The use of sustainable materials and designs can significantly reduce the environmental impact of automotive connecting rods. Manufacturers are increasingly exploring materials that are recyclable, sourced responsibly, or have a lower environmental impact. Additionally, designs that optimize the use of materials and enhance the product’s lifespan can contribute to sustainability.

Eco-friendly Designs

Eco-friendly designs aim to optimize the use of materials, improve the product’s lifespan, and reduce waste. This could involve designing connecting rods that are lighter (reducing material usage) or that have a longer lifespan (reducing the need for replacement).

Company Initiatives towards Sustainability

Many companies, in addition to their sustainable manufacturing practices, undertake various initiatives to further their commitment to environmental sustainability. These can include investing in renewable energy, participating in carbon offset programs, or implementing sustainability training for their employees.

For more detailed information about sustainability practices in the automotive industry, you can refer to the Sustainable Automotive Engineering page on Wikipedia.

Conclusion

The automotive connecting rod industry is a complex and dynamic field, with a variety of manufacturers offering a wide range of products. By examining their global presence, product ranges, manufacturing techniques, quality control procedures, and sustainability initiatives, we can gain a more comprehensive understanding of this industry and its key players.

One such prominent player is FEDA, which has established a strong reputation in the industry through its extensive product range, advanced manufacturing techniques, and rigorous quality control procedures. FEDA’s commitment to sustainability and eco-friendly manufacturing practices further exemplifies the company’s dedication to not only meeting but also exceeding industry standards.

Key Takeaways

- The automotive connecting rod industry comprises various manufacturers, each with unique strengths and product offerings.

- Advanced materials and manufacturing techniques are crucial in the production of high-quality connecting rods.

- Rigorous quality control procedures and certifications are fundamental to ensuring product reliability and customer satisfaction.

- Sustainability is an increasingly important aspect of the manufacturing process, with many manufacturers adopting eco-friendly practices and sustainable designs.