Installing connecting rods to a crankshaft involves careful preparation and precise assembly. Key steps include preparing the components, aligning the rod and crankshaft, and properly torquing the connecting rod bolts.

Component Preparation: Cleanliness is Key

Prior to installing connecting rods to a crankshaft, the components must be thoroughly cleaned. This includes removing any oil, grease, or debris from the connecting rod and crankshaft surfaces. Cleanliness helps prevent premature wear and ensures optimal performance of the engine.

Aligning the Connecting Rod and Crankshaft

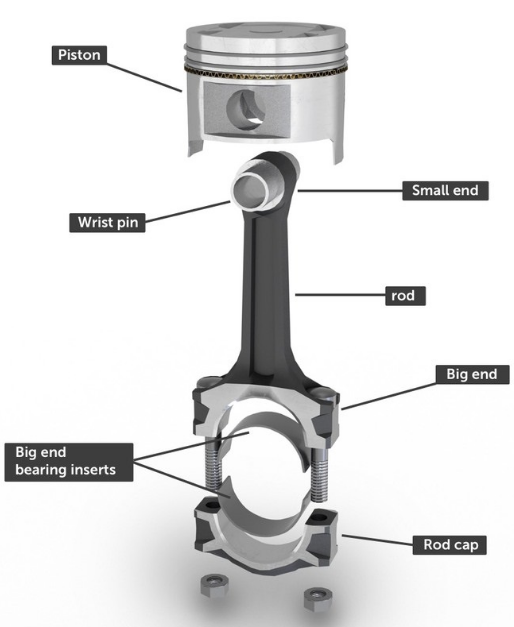

Proper alignment is crucial when installing connecting rods to a crankshaft. The rod must be positioned correctly on the crankshaft to ensure smooth engine operation. This involves orienting the rod so that the bearing surfaces align with the crankshaft journals. It’s also important to ensure that the rod is not twisted or bent, as this can cause misalignment and potential engine damage.

Torquing the Connecting Rod Bolts

Once the connecting rod is properly aligned on the crankshaft, the rod bolts can be installed and torqued. Torque specifications can vary depending on the engine make and model, so it’s essential to refer to the manufacturer’s specifications. Proper torque ensures a secure connection between the rod and crankshaft, which is vital for engine performance and longevity.

Post-Installation Checks and Balancing

After installation, it’s important to perform a final check to ensure proper alignment and torque. The engine should be manually rotated to verify smooth operation. Additionally, the engine may need to be balanced post-installation. Balancing involves adjusting the weight distribution of the engine components to minimize vibration and maximize performance.

Regular Maintenance and Inspection

Regular maintenance and inspection of the connecting rods and crankshaft are key to prolonging engine life. This includes checking for signs of wear, such as scoring or pitting on the bearing surfaces, and ensuring that the rods are properly torqued and aligned.

In conclusion, installing connecting rods to a crankshaft involves careful preparation, precise alignment, proper torquing, and post-installation checks. These steps are crucial for ensuring smooth engine operation and longevity. By following these guidelines, you can help maximize the performance and lifespan of your engine.