Forged Connecting Rod Manufacturing Process Unveiled delves into the intricate world of manufacturing high-performance connecting rods through the forging process. This process yields stronger, more reliable connecting rods that can withstand the rigors of high-performance engines. In this article, we will explore the steps involved in the forged connecting rod manufacturing process, from material selection to forging, machining, and quality control.

Material selection is a critical aspect of the forged connecting rod manufacturing process. Common materials include steel, aluminum, and titanium, each offering unique advantages and disadvantages in terms of strength, weight, and fatigue resistance.

The first step in the forging process is heating the selected metal billet. The billet is heated to a specific temperature, depending on the material, to achieve optimal forgeability without compromising its structural integrity.

Once the metal billet reaches the desired temperature, it is shaped into the connecting rod form using compressive forces. This is typically done using a forging press or a forging hammer. The compressive forces realign the metal’s grain structure, resulting in a stronger and more fatigue-resistant component.

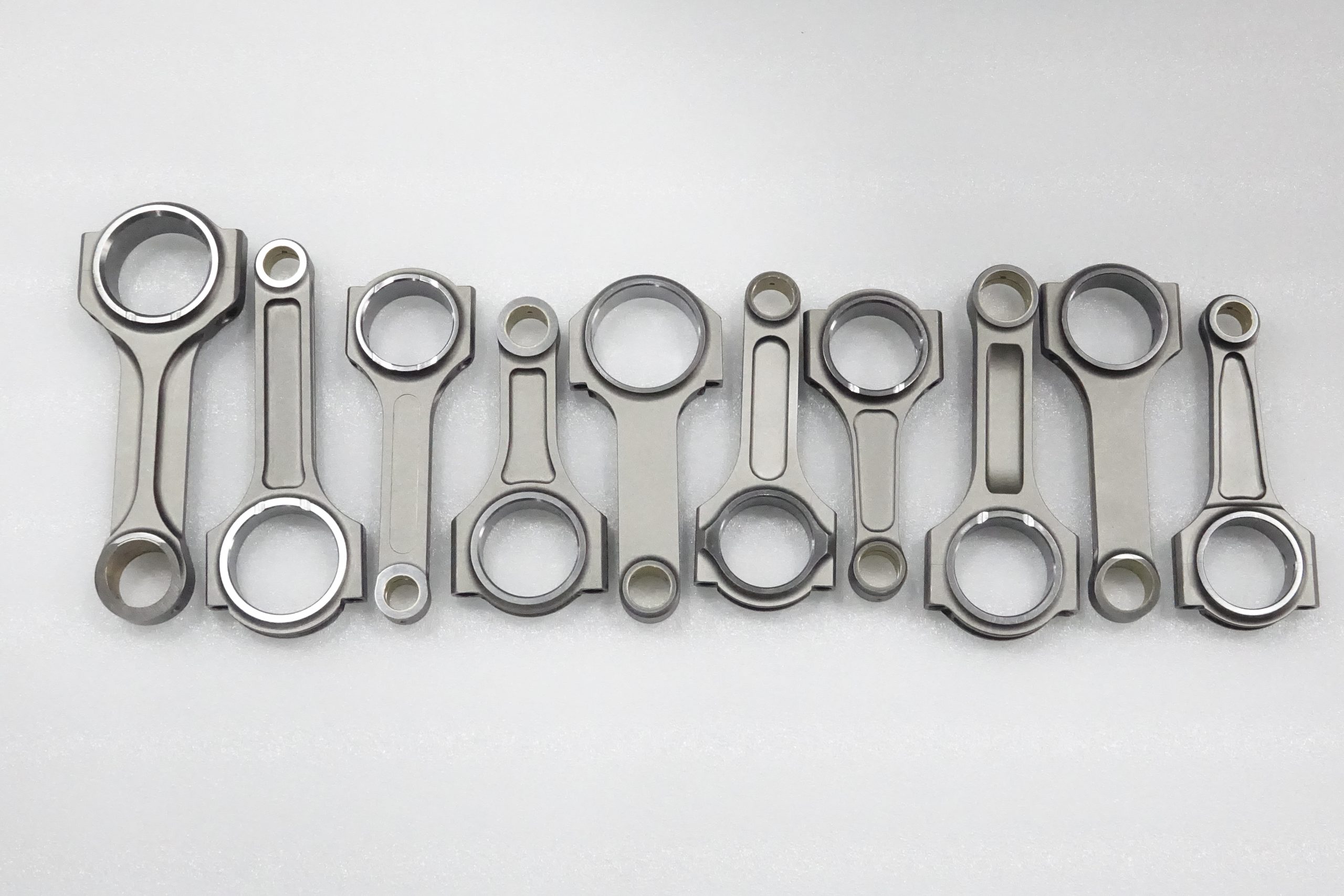

After forging, the connecting rod undergoes machining to achieve its final shape and dimensions. This process includes cutting, grinding, and polishing to ensure that the connecting rod meets the required specifications. Precision machining is crucial for ensuring the proper fit and function of the connecting rod within the engine.

Quality control is an essential aspect of the forged connecting rod manufacturing process. Inspections are performed throughout the process to ensure that each connecting rod meets the required specifications and tolerances. Common inspection methods include dimensional checks, surface finish measurements, and non-destructive testing techniques such as x-ray or ultrasonic testing.

In conclusion, the forged connecting rod manufacturing process involves a series of intricate steps, from material selection to forging, machining, and quality control. Each stage plays a vital role in creating a high-performance connecting rod capable of withstanding the extreme forces and high RPMs found in performance engines. By understanding the forged connecting rod manufacturing process, we can appreciate the effort and expertise required to craft these exceptional engine components.